PFM Crowns Dental Lab

-

10+ years experience for China dental lab outsourcing services -

Processing 10,000 dental cases each month -

4 days Turnround time -

5 years warranty support

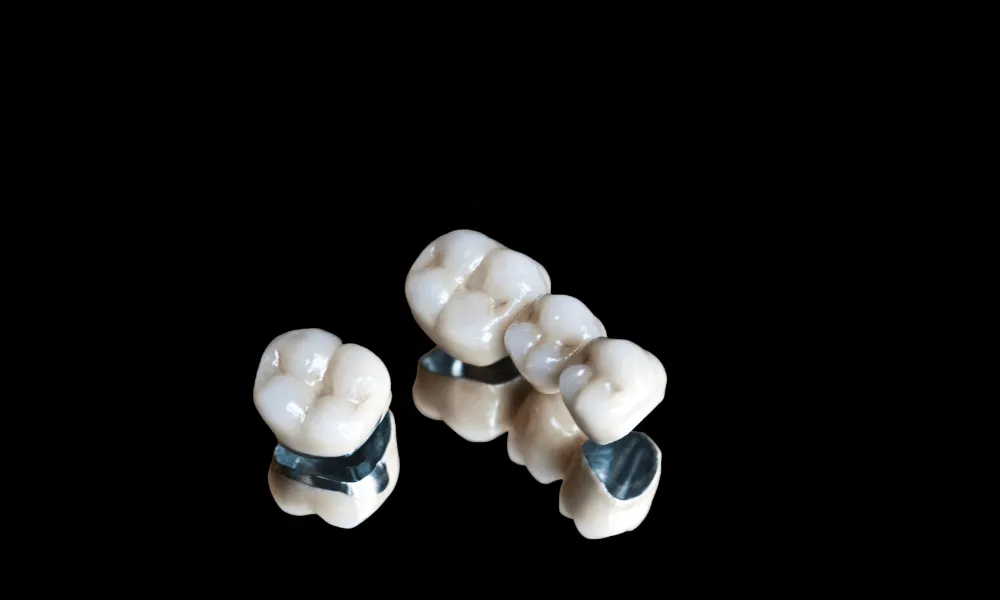

Raytops PFM Crowns

A PFM (Porcelain Fused to Metal) crown combines a strong metal base with a porcelain layer, offering a durable yet natural-looking solution for dental restorations. While all-ceramic crowns, such as zirconia and E.max, are gaining popularity—especially for front teeth—PFM crowns remain a more affordable option without compromising on quality and function. At Raytops Dental Lab, we use advanced technology and traditional craftsmanship to create PFM crowns that ensure precise fit, long-lasting durability, and a natural aesthetic. Our process includes digital dental modeling, CAD/CAM design, laser printing, metal trimming, opaque layer application, porcelain build-up, contouring, and glazing. The process of making PFM crowns is more complex than that of all-ceramic crowns, but at Raytops, we never skip any steps. Our experienced team follows each procedure meticulously to guarantee the highest quality and aesthetics, ensuring that each PFM crown meets the patient’s functional and cosmetic needs.

Featured Crowns & Bridge Dental

Hi Noble

Gold-based alloy crowns fused with layered ceramic for optimal esthetics, soft tissue compatibility, and corrosion resistance. Ideal for anterior or highly visible posterior restorations.

-

Use Case:

Esthetic zones requiring strength and biocompatibility; patients with metal sensitivities or high oral acidity -

Key Benefit:

Excellent long-term color stability, reduced oxide layer, premium finish -

Recommended For:

Cosmetic-driven clinics, private practices, and premium-tier insurance patients

Semi-precious PFM Crowns

Porcelain Fused to Metal Crowns fabricated using palladium-based or silver-based alloys fused with ceramic. Offers a cost-effective balance between strength, esthetics, and biocompatibility.

-

Use Case:

Everyday single-unit and bridge restorations in posterior or low-visibility areas -

Key Benefit:

Good strength-to-cost ratio, dependable marginal integrity, reduced porcelain fracture risk -

Recommended For:

High-volume practices, DSOs, and value-driven private clinics

Full Cast Crown & Bridge

Metal-only restorations without porcelain layering. Precision-cast or milled from selected alloys for exceptional durability and long-term wear resistance.

-

Use Case:

Posterior molars, bruxism patients, or full-metal bridges requiring maximum occlusal load handling -

Key Benefit:

No chipping risk, long-lasting occlusal contact, easy polish and adjustability chairside -

Recommended For:

Cases with limited vertical space, posterior function-focused areas, or insurance-specified materials

PFM Crowns Built for Strength, Esthetics, and Predictable Fit

Trusted PFM & Full-Cast Restorations – A Proven Standard Still Going Strong

At Raytops, we produce high-precision porcelain-fused-to-metal (PFM) crowns and bridges — built with alloy options tailored to your case, budget, and esthetic demands.

Whether your patient needs a durable posterior crown with strong masking ability, or a full-cast solution for high-load areas, our technician-guided workflows ensure consistent fit, reliable bonding, and predictable esthetic outcomes.

🧩 What We Deliver

-

Hi-Noble PFM Crowns – Gold-based alloys with superior biocompatibility and esthetics

-

Semi-Precious PFM Crowns – Palladium or silver alloys for balance between strength and cost

-

Full Cast Crowns & Bridges – Non-layered, high-strength metal restorations for posterior zones

All restorations are layered or polished in-house, verified for marginal integrity, occlusion, and shade harmony.

✅ Why Choose Raytops for PFM Restorations?

-

Alloy flexibility – Choose by case type, region, or insurance category

-

Digital & traditional workflows – STL-ready or impression-based

-

Consistent porcelain layering – Natural esthetics across shade guides

-

Low remake rate – Due to precise marginal fit and firing control

-

Batch traceability – Each crown linked to its specific alloy lot and technician

From single posteriors to full-arch frameworks, Raytops ensures every metal-based restoration performs with reliability — clinically and financially.

Material Types & Comparison

Alloy Options That Match Clinical Reality

The metal beneath your porcelain matters. From gold-rich hi-noble alloys to cost-effective semi-precious blends, our alloy selection ensures your crown works — not just looks right.

📊 PFM & Full Cast Alloy Comparison Table

| Alloy Type | Composition Example | Biocompatibility | Esthetics Under Porcelain | Cost Level | Clinical Notes |

|---|---|---|---|---|---|

| Hi-Noble Alloy | >40% Gold (e.g. Au-Pd) | ★★★★★ | ★★★★★ | $$$$$ | Ideal for anterior esthetics, soft tissue-friendly |

| Semi-Precious Alloy | Pd-Ag / Pd-Cu blends | ★★★★☆ | ★★★★☆ | $$$ | Good shading control, stable oxide layer |

| Base Metal (Non-precious) | Ni-Cr / Co-Cr | ★★★☆☆ | ★★☆☆☆ | $$ | High strength, but possible tissue reactivity in sensitive patients |

| Full Cast (Non-layered) | Any above, no ceramic | ★★★★☆ | N/A | $$–$$$$ | Pure function, excellent durability |

🧠 Material Selection Guidance

-

Anterior Zone (esthetic priority) → Hi-Noble PFM for best shade transmission and soft tissue response

-

Posterior with cost sensitivity → Semi-precious alloy or full-cast for maximum load & longevity

-

Insurance-driven restorations → Select base metal options where permitted, with reinforced margins

-

Long-span bridges → Pd-based alloy preferred due to thermal compatibility and low oxidation

Every crown starts with the right foundation. We help ensure your material choice aligns with the tooth’s job — and your patient’s long-term comfort.

🔐 Raytops Alloy Management

-

Certified by composition (%Au / %Pd / %Ag / %Ni / %Cr)

-

Traceable to batch and logged per case for reporting

-

Soft metal polishing, margin reinforcement, and connector sizing per framework

Dental lab Digital Workflow

Digitally Compatible. Technically Reliable.

PFM restorations demand more than just a scan — they require anatomical accuracy, clean margin capture, and ceramic-to-metal bonding precision. At Raytops, we integrate technician oversight with digital workflows to ensure consistency from scan to final glaze.

🧩 PFM & Full Cast Workflow Overview

1️⃣ Data Intake

-

Accepts both STL scans and traditional impressions / stone models

-

STL submissions from iTero, 3Shape, Medit, Carestream, etc.

-

Case-specific notes accepted: metal type, margin line, connector design

2️⃣ CAD Design & Framework Planning

-

Coping thickness designed based on span, zone, and alloy type

-

Pontic and connector zones customized for load-bearing areas

-

Control over cutback depth, ceramic support angle, full-cast bypass if requested

3️⃣ CAM Fabrication

-

Coping / framework: CNC milled (precious metals) or lost-wax cast (semi-precious/base)

-

Optional sandblasting or oxidation before layering

-

Full cast crowns milled or cast per alloy behavior

4️⃣ Porcelain Application

-

Manual layering using VITA / Noritake compatible ceramics

-

Shade matching based on supplied photos / tabs

-

Staining and glazing adjusted per lighting temperature, adjacent dentition

5️⃣ QC & Final Polish

-

Verified margins, interproximal fit, and occlusion

-

Polish for full cast (or light glaze if specified)

-

Delivery in marked bags with material ID and batch reference

✅ Why Technicians Still Matter

“PFM is not plug-and-play — even in digital workflows. Every margin angle, porcelain cutback, or coping vent matters. That’s why we review every case with a lab-trained eye.”

Customization – Product Fits Reference

Your Case, Your Protocol – We Follow Precisely

No two crowns are the same — especially when it comes to porcelain layering, margin design, or functional adjustments. Raytops offers detailed customization options to match your clinical and esthetic expectations.

🧩 Customization Options We Support

| Feature | Description |

|---|---|

| Alloy Type Selection | Choose hi-noble, semi-precious, or non-precious by case or patient request |

| Porcelain Cutback Depth | Define exact mm reduction for esthetic zones or functional ceramic areas |

| Coping Design | Specify full-coverage, metal collar, or windowed facial porcelain zones |

| Margin Design Matching | Feather, shoulder, or chamfer — scanned or model-verified |

| Shade & Characterization | VITA Classic, 3D Master, or custom photo-matched (photos or tab required) |

| Staining/Glazing Adjustments | Age simulation, translucency, or warmth tuning |

| Full Cast Polish Preference | High-gloss, satin, or occlusal relief depending on chairside preference |

🧠 Technician Insight:

“Some doctors prefer a lingual metal collar for posterior PFMs — we note that in the design stage and confirm ceramic wrap height to avoid future fractures.”

📦 Packaging & Case Identification

-

Patient initials, clinic codes, or case numbers can be added to bags

-

OEM/neutral packaging supported for group clients or resellers

-

Color-coding by alloy type available for clinics handling mixed batches

Give us the specs. We’ll give you consistency — crown after crown.

Clinical Applications & Indications

PFM and Full Cast Crowns Still Play a Critical Role in Daily Restorative Dentistry

From high-strength posterior units to insurance-specified full metal restorations, our crowns serve daily cases where reliability and cost control matter most.

📋 Typical Clinical Scenarios & Product Mapping

| Clinical Scenario | Recommended Product | Key Reason |

|---|---|---|

| Posterior single crown with deep occlusal load | Full Cast Crown | Maximum strength, no chipping risk |

| Patient with metal allergy concern + esthetic demand | Hi-Noble PFM | Biocompatibility + shade layering |

| Long-span posterior bridge | Semi-Precious PFM | Stable oxide layer, controlled ceramic firing |

| Molar crown in cost-sensitive practice | Base Metal PFM | Economic, durable, easy to polish |

| Anterior unit with limited prep space | Hi-Noble PFM (thin coping) | Excellent masking with minimal thickness |

| DSO or group with insurance coding limits | Full Cast or Base PFM | Consistent with billing rules & codes |

🤝 How We Support Your Case Execution

-

Margin clarity feedback on scans or models (we flag issues pre-fabrication)

-

Custom occlusal relief based on patient parafunction (e.g. bruxism zones)

-

Return notes for difficult fits or prep angles — included with case report

-

Optional crown trial on long-span bridges (digital or model try-in)

🧠 Technician Note:

“For clinics serving elderly or long-term denture wearers, we often suggest full cast for posteriors — it’s adjust-and-go, no porcelain stress.”

We don’t just fabricate crowns — we fit into your restorative flow. And that means knowing when full-cast reliability is the best solution.

Product & Material Selection Guide

Find the Right Crown Type for Your Case

Each patient, prep, and budget is different. Use this quick guide to select the PFM or full-cast restoration that matches your priorities.

📊 Product Selection by Clinical Priority

| Clinical Focus | Recommended Option | Why This Choice Works Best |

|---|---|---|

| Long-term esthetics + tissue health | Hi-Noble PFM | Gold-based alloy offers best shade stability and soft tissue response |

| Cost efficiency + daily durability | Semi-Precious PFM | Affordable with consistent strength and masking |

| Function-only molars or bruxism | Full Cast Crown | No risk of porcelain fracture, easy chairside adjust |

| Insurance-driven restoration | Base Metal PFM / Cast | Fits most reimbursement frameworks and coding |

| Lab-to-lab outsourcing | Mixed batch supported | Combine Hi-Noble, Semi-precious, and Cast in one case |

⚙️ Material Comparison Snapshot

| Alloy Type | Esthetics | Strength | Cost Efficiency | Biocompatibility |

|---|---|---|---|---|

| Hi-Noble | ★★★★★ | ★★★★☆ | ★★☆☆☆ | ★★★★★ |

| Semi-Precious | ★★★★☆ | ★★★★☆ | ★★★☆☆ | ★★★★☆ |

| Base Metal | ★★☆☆☆ | ★★★★★ | ★★★★★ | ★★☆☆☆ |

| Full Cast (Any) | N/A | ★★★★★ | ★★★★☆ | ★★★★☆ |

🧠 Case Tip:

“If you’re restoring a full-arch with both functional and esthetic zones, many clients mix Hi-Noble for anteriors and Full Cast for molars — all under one scan submission.”

We don’t force a single solution. We help you combine the right ones — by site, by budget, by result.

Why Partner with Raytops for Removable Solutions

PFM Restorations That Just Fit – Because They’re Made by Technicians Who Understand Why They Don’t

Unlike monolithic restorations, PFM and full-cast crowns rely heavily on technician intuition, layering logic, and thermal stability. That’s why clinics and labs trust Raytops to deliver restorations that seat predictably — and perform long term.

✅ What Makes Our PFM Program Different

🛠️ Technician-Led Case Planning

-

Each case is reviewed for coping design, margin type, and connector logic

-

Porcelain cutbacks, collar requests, and esthetic zones flagged manually

-

Functional contacts evaluated using scan occlusion or stone articulation

📦 Batch-Controlled Alloy Management

-

Alloy composition documented and traceable by case

-

Option to mix alloy types within a single case submission (e.g. gold anterior, full-cast posterior)

-

Full material disclosure per unit with lot trace reference

🔁 Low Adjustment & Remake Rates

-

Pre-seating contacts adjusted digitally or manually based on protocol

-

Known for marginal accuracy and esthetic color consistency

-

First-fit success rate exceeds 94% on PFM cases in 2024 review

🔧 Traditional + Digital Workflow Integration

-

Accepts impressions, models, or STL

-

Supports DSO/lab batch submission workflows

-

Handles mixed-material, multi-unit bridge cases under one case ID

🌐 Export & OEM-Ready

-

CE/FDA-compliant metal usage

-

OEM labeling, packaging by alloy/color/clinic available

-

Responsive English/Mandarin support team to coordinate submission and remake tracking

“In PFM, it’s never just about metal and ceramic — it’s about how they work together.

We make sure they do.”

Real Cases. Real Results.

Clinics and Labs Worldwide Trust Raytops for Precision-Made PFM Restorations

📍 Case 1: U.S. Multi-Location Clinic Standardizes Posterior Workflow with Mixed Alloy Crowns

Challenge:

The clinic served both private-pay and insurance patients and needed to use hi-noble for anteriors and full cast for molars, but didn’t want to split vendors.

Solution:

Raytops built a unified digital submission template. STL scans were processed under one case ID, with different alloy instructions tagged per unit.

Result:

-

Turnaround reduced from 10 to 6 days

-

Over 95% of crowns seated without occlusal adjustment

-

Staff preferred Raytops labeling for its clarity

🗨️ “They don’t force a one-size crown. They follow exactly what we send — unit by unit.”

— Clinical Director, California

📍 Case 2: Australian Lab Replaced In-House Casting with Raytops Semi-Precious PFM Line

Challenge:

A regional lab struggled with rising alloy costs and inconsistent coping fits in their in-house casting process.

Solution:

They outsourced their PFM copings to Raytops, specifying alloy type and ceramic layering zones digitally.

Result:

-

Reduced remakes by 42%

-

Gained full traceability for metal batch and framework

-

Clients reported more consistent esthetic results

🗨️ “We no longer waste time adjusting coping fits — they just seat.”

— Lab Owner, Sydney

📍 Case 3: DSO Group in Europe Used Raytops to Replace Local Casting for Posterior Full Metal Units

Challenge:

High-cost local casting created margin inconsistency and delayed delivery in high-volume full metal posterior crowns.

Solution:

Raytops offered full-cast Co-Cr units polished to requested finish (high-gloss or matte) with minimal occlusal relief.

Result:

-

Delivery down to 4 days (from 9)

-

90% crowns seated chairside without polish adjustments

-

Doctors requested “Raytops metal polish finish” in internal SOP

🗨️ “It’s not just a lab; it’s a casting partner we can trust at scale.”

— Procurement Lead, EU DSO

Certifications & Regulatory Assurance

Material-Safe. Globally Cleared. Technically Verified.

Our PFM and full-cast restorations are crafted using certified dental alloys and porcelain systems — with compliance documentation to match your region’s import and clinical requirements.

📄 Certifications & Documents Available

| Certificate / Document | Relevance to PFM & Full Cast Products |

|---|---|

| ISO 13485:2016 | Medical device manufacturing system |

| FDA Device Listing (USA) | Registered for dental crowns and prosthetics |

| CE Declaration of Conformity | All alloy and ceramic systems used |

| MSDS (Material Safety Data Sheets) | Available for all alloys (Hi-Noble, Pd-Ag, Co-Cr) |

| Alloy Composition Certificate | Per order, by batch, with %Au / Pd / Ni / Cr etc. |

| Certificate of Origin / Form A | For import/export and customs clearance |

| RoHS / REACH Compliance | On request for certain regions (EU/UK) |

🧪 Our Alloy & Ceramic Systems Are:

-

Biocompatibility-tested under ISO 10993

-

Fired using VITA/Noritake-compatible layering systems

-

Tracked per technician + casting batch for quality traceability

-

Supplied with optional labeling formats (OEM/private label)

🧠 Technician Insight:

“Every crown carries a QR-coded ID linking to its alloy batch and processing date. Labs and DSOs can access those logs anytime for audit or material traceability.”

Frequently Asked Questions

Frequently Asked Questions – PFM & Full Cast

Q1: Can I submit both digital scans and physical impressions for PFM cases?

Yes. We accept STL files (from 3Shape, iTero, Medit, etc.) and traditional models or impressions. Mixed workflows are common — we process both with consistent margin integrity.

Q2: How do I specify which alloy to use for each crown in a multi-unit case?

When uploading files or submitting the order form, indicate the alloy per unit. Our technicians tag each substructure accordingly and label them in the final delivery bags.

Q3: What’s your typical turnaround time for PFM and full-cast crowns?

-

PFM (any alloy): 5–7 working days

-

Full Cast Crowns/Bridges: 4–6 working days

Shipping time varies by region (typically 2–5 days via DHL/FedEx/UPS).

Q4: Do you offer remake support if a PFM doesn’t fit properly?

Yes. If the margin or seating issue results from processing error (not prep or impression), we remake it at no charge under our standard remake policy. Case documentation is reviewed first.

Q5: Can I request a metal collar or specify coping cutback for PFM units?

Absolutely. You can indicate collar design (facial, lingual, 360°) and we follow your coping/porcelain zone instructions. If not specified, we follow standard esthetic protocol based on tooth position.

Q6: Do you offer OEM or neutral-label packaging for PFM restorations?

Yes. We can pack crowns under your brand or in neutral format. Bags can include patient code, shade, alloy type, and case ID. Barcodes or QR codes available on request.

Q7: How are your alloys certified and tracked?

Each batch of alloy used is documented and traceable. We provide alloy composition certificates and MSDS files upon request. Lot numbers are logged per crown for audit-ready traceability.

Q8: Can I combine multiple materials (e.g., Hi-Noble + Full Cast) in one case?

Yes. Our system allows you to submit one case with different alloy instructions per unit. These are processed, verified, and packed accordingly, with color-coded or labeled alloy type.

Have more questions about alloy selection, turnaround, or digital compatibility?

→ [Talk to a Technician]

Q1: Can I send intraoral scan data for dentures or guards?

Yes. We accept STL files from all major scanners. For dentures, we also support digital setups based on scanned wax-ups or try-ins. Night guards and sports guards can be made fully from scan.

Q2: What’s your turnaround time for removable appliances?

-

Acrylic dentures or partials: 4–6 working days

-

Flexible partials: 5–6 working days

-

Night guards & sports guards: 3–5 working days

Shipping times vary by region (typically 2–5 days via DHL, UPS, or FedEx).

Q3: Can I combine analog and digital materials in one case?

Absolutely. Many clients send a stone model for the denture and a scan for the opposing. We adapt the workflow to fit your case.

Q4: Do you offer custom labeling or white-label shipping?

Yes. We provide OEM packaging, patient ID labeling, and custom invoices for labs or distributors.

Q5: What if a denture doesn’t fit properly?

First, we review case inputs and model accuracy. If the issue is confirmed (e.g., misfit due to model defect or unclear border), we offer free remakes within our quality policy. Adjustment guides are also available.

Q6: Can I order bulk units for a school, nursing home, or public project?

Yes. We handle high-volume removable programs with pre-tagged labeling, color selection, and batch packaging. Contact us for a quote or demo set.

Q7: How can I communicate design preferences (tooth shape, shade, etc.)?

You can upload instructions, intraoral photos, shade tabs, and even bite scan notes with your order. For repeat doctors, we save preferences in our client system.

Q8: Do you support metal frameworks for partials?

Yes. We offer cobalt-chrome frameworks with digitally designed clasps and occlusal rests. We also verify opposing occlusion if files are provided.

Still have questions? Our removable case coordinators can walk you through your first few cases and ensure a smooth start.

Trends & Future Outlook in Implant Restorations

The Future of PFM & Full Cast Restorations Isn’t Over — It’s Just Smarter

While zirconia and lithium disilicate dominate the headlines, porcelain-fused-to-metal and full-cast restorations still serve millions of patients worldwide. And they’re evolving, not vanishing.

🔍 1. Selective Use Over Replacement

Clinicians today are smarter in matching material to indication.

Full cast molars? Still unbeaten in bruxism cases.

PFM bridges? Often the safest call when span, cost, and shade all matter.

✅ Raytops Insight:

We help you mix materials within one digital workflow — full-cast posterior, PFM anterior, all on a single scan submission.

🧪 2. Alloy Engineering Is Improving

Modern semi-precious and high-noble alloys show better porcelain bonding, lower oxide staining, and improved biocompatibility — even in patients previously considered “metal-sensitive.”

✅ Raytops Insight:

We use CE/FDA-certified alloys with known oxide performance curves — reducing porcelain delamination and esthetic shade drift over time.

⚙️ 3. Digitization Brings New Life to Traditional Restorations

The fusion of CAD design, CNC milling of copings, and ceramic firing with digitally defined cutbacks brings unprecedented accuracy to even the most “manual” crown type.

✅ Raytops Insight:

Every PFM case we touch passes through a technician-verified CAD step — even if it starts with an analog impression.

🌍 4. Global Cost Pressures Favor Durable, Proven Options

In many public health systems, PFM and full-cast crowns remain reimbursable standards. For cost-sensitive markets, they offer the best ratio of longevity to spend.

✅ Raytops Insight:

We serve both premium cosmetic practices and national group contracts — with flexible alloy tiering per zone.

🧠 The Takeaway?

PFM isn’t outdated — it’s strategic.

Full Cast isn’t basic — it’s reliable.

The future isn’t always about new materials. It’s about using the right ones, the right way — and Raytops is here to help you do that.

Alloy Options That Match Clinical Reality

The metal beneath your porcelain matters. From gold-rich hi-noble alloys to cost-effective semi-precious blends, our alloy selection ensures your crown works — not just looks right.

📊 PFM & Full Cast Alloy Comparison Table

| Alloy Type | Composition Example | Biocompatibility | Esthetics Under Porcelain | Cost Level | Clinical Notes |

|---|---|---|---|---|---|

| Hi-Noble Alloy | >40% Gold (e.g. Au-Pd) | ★★★★★ | ★★★★★ | $$$$$ | Ideal for anterior esthetics, soft tissue-friendly |

| Semi-Precious Alloy | Pd-Ag / Pd-Cu blends | ★★★★☆ | ★★★★☆ | $$$ | Good shading control, stable oxide layer |

| Base Metal (Non-precious) | Ni-Cr / Co-Cr | ★★★☆☆ | ★★☆☆☆ | $$ | High strength, but possible tissue reactivity in sensitive patients |

| Full Cast (Non-layered) | Any above, no ceramic | ★★★★☆ | N/A | $$–$$$$ | Pure function, excellent durability |

🧠 Material Selection Guidance

-

Anterior Zone (esthetic priority) → Hi-Noble PFM for best shade transmission and soft tissue response

-

Posterior with cost sensitivity → Semi-precious alloy or full-cast for maximum load & longevity

-

Insurance-driven restorations → Select base metal options where permitted, with reinforced margins

-

Long-span bridges → Pd-based alloy preferred due to thermal compatibility and low oxidation

Every crown starts with the right foundation. We help ensure your material choice aligns with the tooth’s job — and your patient’s long-term comfort.

🔐 Raytops Alloy Management

-

Certified by composition (%Au / %Pd / %Ag / %Ni / %Cr)

-

Traceable to batch and logged per case for reporting

-

Soft metal polishing, margin reinforcement, and connector sizing per framework

Digitally Compatible. Technically Reliable.

PFM restorations demand more than just a scan — they require anatomical accuracy, clean margin capture, and ceramic-to-metal bonding precision. At Raytops, we integrate technician oversight with digital workflows to ensure consistency from scan to final glaze.

🧩 PFM & Full Cast Workflow Overview

1️⃣ Data Intake

-

Accepts both STL scans and traditional impressions / stone models

-

STL submissions from iTero, 3Shape, Medit, Carestream, etc.

-

Case-specific notes accepted: metal type, margin line, connector design

2️⃣ CAD Design & Framework Planning

-

Coping thickness designed based on span, zone, and alloy type

-

Pontic and connector zones customized for load-bearing areas

-

Control over cutback depth, ceramic support angle, full-cast bypass if requested

3️⃣ CAM Fabrication

-

Coping / framework: CNC milled (precious metals) or lost-wax cast (semi-precious/base)

-

Optional sandblasting or oxidation before layering

-

Full cast crowns milled or cast per alloy behavior

4️⃣ Porcelain Application

-

Manual layering using VITA / Noritake compatible ceramics

-

Shade matching based on supplied photos / tabs

-

Staining and glazing adjusted per lighting temperature, adjacent dentition

5️⃣ QC & Final Polish

-

Verified margins, interproximal fit, and occlusion

-

Polish for full cast (or light glaze if specified)

-

Delivery in marked bags with material ID and batch reference

✅ Why Technicians Still Matter

“PFM is not plug-and-play — even in digital workflows. Every margin angle, porcelain cutback, or coping vent matters. That’s why we review every case with a lab-trained eye.”

Your Case, Your Protocol – We Follow Precisely

No two crowns are the same — especially when it comes to porcelain layering, margin design, or functional adjustments. Raytops offers detailed customization options to match your clinical and esthetic expectations.

🧩 Customization Options We Support

| Feature | Description |

|---|---|

| Alloy Type Selection | Choose hi-noble, semi-precious, or non-precious by case or patient request |

| Porcelain Cutback Depth | Define exact mm reduction for esthetic zones or functional ceramic areas |

| Coping Design | Specify full-coverage, metal collar, or windowed facial porcelain zones |

| Margin Design Matching | Feather, shoulder, or chamfer — scanned or model-verified |

| Shade & Characterization | VITA Classic, 3D Master, or custom photo-matched (photos or tab required) |

| Staining/Glazing Adjustments | Age simulation, translucency, or warmth tuning |

| Full Cast Polish Preference | High-gloss, satin, or occlusal relief depending on chairside preference |

🧠 Technician Insight:

“Some doctors prefer a lingual metal collar for posterior PFMs — we note that in the design stage and confirm ceramic wrap height to avoid future fractures.”

📦 Packaging & Case Identification

-

Patient initials, clinic codes, or case numbers can be added to bags

-

OEM/neutral packaging supported for group clients or resellers

-

Color-coding by alloy type available for clinics handling mixed batches

Give us the specs. We’ll give you consistency — crown after crown.

PFM and Full Cast Crowns Still Play a Critical Role in Daily Restorative Dentistry

From high-strength posterior units to insurance-specified full metal restorations, our crowns serve daily cases where reliability and cost control matter most.

📋 Typical Clinical Scenarios & Product Mapping

| Clinical Scenario | Recommended Product | Key Reason |

|---|---|---|

| Posterior single crown with deep occlusal load | Full Cast Crown | Maximum strength, no chipping risk |

| Patient with metal allergy concern + esthetic demand | Hi-Noble PFM | Biocompatibility + shade layering |

| Long-span posterior bridge | Semi-Precious PFM | Stable oxide layer, controlled ceramic firing |

| Molar crown in cost-sensitive practice | Base Metal PFM | Economic, durable, easy to polish |

| Anterior unit with limited prep space | Hi-Noble PFM (thin coping) | Excellent masking with minimal thickness |

| DSO or group with insurance coding limits | Full Cast or Base PFM | Consistent with billing rules & codes |

🤝 How We Support Your Case Execution

-

Margin clarity feedback on scans or models (we flag issues pre-fabrication)

-

Custom occlusal relief based on patient parafunction (e.g. bruxism zones)

-

Return notes for difficult fits or prep angles — included with case report

-

Optional crown trial on long-span bridges (digital or model try-in)

🧠 Technician Note:

“For clinics serving elderly or long-term denture wearers, we often suggest full cast for posteriors — it’s adjust-and-go, no porcelain stress.”

We don’t just fabricate crowns — we fit into your restorative flow. And that means knowing when full-cast reliability is the best solution.

Find the Right Crown Type for Your Case

Each patient, prep, and budget is different. Use this quick guide to select the PFM or full-cast restoration that matches your priorities.

📊 Product Selection by Clinical Priority

| Clinical Focus | Recommended Option | Why This Choice Works Best |

|---|---|---|

| Long-term esthetics + tissue health | Hi-Noble PFM | Gold-based alloy offers best shade stability and soft tissue response |

| Cost efficiency + daily durability | Semi-Precious PFM | Affordable with consistent strength and masking |

| Function-only molars or bruxism | Full Cast Crown | No risk of porcelain fracture, easy chairside adjust |

| Insurance-driven restoration | Base Metal PFM / Cast | Fits most reimbursement frameworks and coding |

| Lab-to-lab outsourcing | Mixed batch supported | Combine Hi-Noble, Semi-precious, and Cast in one case |

⚙️ Material Comparison Snapshot

| Alloy Type | Esthetics | Strength | Cost Efficiency | Biocompatibility |

|---|---|---|---|---|

| Hi-Noble | ★★★★★ | ★★★★☆ | ★★☆☆☆ | ★★★★★ |

| Semi-Precious | ★★★★☆ | ★★★★☆ | ★★★☆☆ | ★★★★☆ |

| Base Metal | ★★☆☆☆ | ★★★★★ | ★★★★★ | ★★☆☆☆ |

| Full Cast (Any) | N/A | ★★★★★ | ★★★★☆ | ★★★★☆ |

🧠 Case Tip:

“If you’re restoring a full-arch with both functional and esthetic zones, many clients mix Hi-Noble for anteriors and Full Cast for molars — all under one scan submission.”

We don’t force a single solution. We help you combine the right ones — by site, by budget, by result.

PFM Restorations That Just Fit – Because They’re Made by Technicians Who Understand Why They Don’t

Unlike monolithic restorations, PFM and full-cast crowns rely heavily on technician intuition, layering logic, and thermal stability. That’s why clinics and labs trust Raytops to deliver restorations that seat predictably — and perform long term.

✅ What Makes Our PFM Program Different

🛠️ Technician-Led Case Planning

-

Each case is reviewed for coping design, margin type, and connector logic

-

Porcelain cutbacks, collar requests, and esthetic zones flagged manually

-

Functional contacts evaluated using scan occlusion or stone articulation

📦 Batch-Controlled Alloy Management

-

Alloy composition documented and traceable by case

-

Option to mix alloy types within a single case submission (e.g. gold anterior, full-cast posterior)

-

Full material disclosure per unit with lot trace reference

🔁 Low Adjustment & Remake Rates

-

Pre-seating contacts adjusted digitally or manually based on protocol

-

Known for marginal accuracy and esthetic color consistency

-

First-fit success rate exceeds 94% on PFM cases in 2024 review

🔧 Traditional + Digital Workflow Integration

-

Accepts impressions, models, or STL

-

Supports DSO/lab batch submission workflows

-

Handles mixed-material, multi-unit bridge cases under one case ID

🌐 Export & OEM-Ready

-

CE/FDA-compliant metal usage

-

OEM labeling, packaging by alloy/color/clinic available

-

Responsive English/Mandarin support team to coordinate submission and remake tracking

“In PFM, it’s never just about metal and ceramic — it’s about how they work together.

We make sure they do.”

Clinics and Labs Worldwide Trust Raytops for Precision-Made PFM Restorations

📍 Case 1: U.S. Multi-Location Clinic Standardizes Posterior Workflow with Mixed Alloy Crowns

Challenge:

The clinic served both private-pay and insurance patients and needed to use hi-noble for anteriors and full cast for molars, but didn’t want to split vendors.

Solution:

Raytops built a unified digital submission template. STL scans were processed under one case ID, with different alloy instructions tagged per unit.

Result:

-

Turnaround reduced from 10 to 6 days

-

Over 95% of crowns seated without occlusal adjustment

-

Staff preferred Raytops labeling for its clarity

🗨️ “They don’t force a one-size crown. They follow exactly what we send — unit by unit.”

— Clinical Director, California

📍 Case 2: Australian Lab Replaced In-House Casting with Raytops Semi-Precious PFM Line

Challenge:

A regional lab struggled with rising alloy costs and inconsistent coping fits in their in-house casting process.

Solution:

They outsourced their PFM copings to Raytops, specifying alloy type and ceramic layering zones digitally.

Result:

-

Reduced remakes by 42%

-

Gained full traceability for metal batch and framework

-

Clients reported more consistent esthetic results

🗨️ “We no longer waste time adjusting coping fits — they just seat.”

— Lab Owner, Sydney

📍 Case 3: DSO Group in Europe Used Raytops to Replace Local Casting for Posterior Full Metal Units

Challenge:

High-cost local casting created margin inconsistency and delayed delivery in high-volume full metal posterior crowns.

Solution:

Raytops offered full-cast Co-Cr units polished to requested finish (high-gloss or matte) with minimal occlusal relief.

Result:

-

Delivery down to 4 days (from 9)

-

90% crowns seated chairside without polish adjustments

-

Doctors requested “Raytops metal polish finish” in internal SOP

🗨️ “It’s not just a lab; it’s a casting partner we can trust at scale.”

— Procurement Lead, EU DSO

Material-Safe. Globally Cleared. Technically Verified.

Our PFM and full-cast restorations are crafted using certified dental alloys and porcelain systems — with compliance documentation to match your region’s import and clinical requirements.

📄 Certifications & Documents Available

| Certificate / Document | Relevance to PFM & Full Cast Products |

|---|---|

| ISO 13485:2016 | Medical device manufacturing system |

| FDA Device Listing (USA) | Registered for dental crowns and prosthetics |

| CE Declaration of Conformity | All alloy and ceramic systems used |

| MSDS (Material Safety Data Sheets) | Available for all alloys (Hi-Noble, Pd-Ag, Co-Cr) |

| Alloy Composition Certificate | Per order, by batch, with %Au / Pd / Ni / Cr etc. |

| Certificate of Origin / Form A | For import/export and customs clearance |

| RoHS / REACH Compliance | On request for certain regions (EU/UK) |

🧪 Our Alloy & Ceramic Systems Are:

-

Biocompatibility-tested under ISO 10993

-

Fired using VITA/Noritake-compatible layering systems

-

Tracked per technician + casting batch for quality traceability

-

Supplied with optional labeling formats (OEM/private label)

🧠 Technician Insight:

“Every crown carries a QR-coded ID linking to its alloy batch and processing date. Labs and DSOs can access those logs anytime for audit or material traceability.”

Frequently Asked Questions – PFM & Full Cast

Q1: Can I submit both digital scans and physical impressions for PFM cases?

Yes. We accept STL files (from 3Shape, iTero, Medit, etc.) and traditional models or impressions. Mixed workflows are common — we process both with consistent margin integrity.

Q2: How do I specify which alloy to use for each crown in a multi-unit case?

When uploading files or submitting the order form, indicate the alloy per unit. Our technicians tag each substructure accordingly and label them in the final delivery bags.

Q3: What’s your typical turnaround time for PFM and full-cast crowns?

-

PFM (any alloy): 5–7 working days

-

Full Cast Crowns/Bridges: 4–6 working days

Shipping time varies by region (typically 2–5 days via DHL/FedEx/UPS).

Q4: Do you offer remake support if a PFM doesn’t fit properly?

Yes. If the margin or seating issue results from processing error (not prep or impression), we remake it at no charge under our standard remake policy. Case documentation is reviewed first.

Q5: Can I request a metal collar or specify coping cutback for PFM units?

Absolutely. You can indicate collar design (facial, lingual, 360°) and we follow your coping/porcelain zone instructions. If not specified, we follow standard esthetic protocol based on tooth position.

Q6: Do you offer OEM or neutral-label packaging for PFM restorations?

Yes. We can pack crowns under your brand or in neutral format. Bags can include patient code, shade, alloy type, and case ID. Barcodes or QR codes available on request.

Q7: How are your alloys certified and tracked?

Each batch of alloy used is documented and traceable. We provide alloy composition certificates and MSDS files upon request. Lot numbers are logged per crown for audit-ready traceability.

Q8: Can I combine multiple materials (e.g., Hi-Noble + Full Cast) in one case?

Yes. Our system allows you to submit one case with different alloy instructions per unit. These are processed, verified, and packed accordingly, with color-coded or labeled alloy type.

Have more questions about alloy selection, turnaround, or digital compatibility?

→ [Talk to a Technician]

Q1: Can I send intraoral scan data for dentures or guards?

Yes. We accept STL files from all major scanners. For dentures, we also support digital setups based on scanned wax-ups or try-ins. Night guards and sports guards can be made fully from scan.

Q2: What’s your turnaround time for removable appliances?

-

Acrylic dentures or partials: 4–6 working days

-

Flexible partials: 5–6 working days

-

Night guards & sports guards: 3–5 working days

Shipping times vary by region (typically 2–5 days via DHL, UPS, or FedEx).

Q3: Can I combine analog and digital materials in one case?

Absolutely. Many clients send a stone model for the denture and a scan for the opposing. We adapt the workflow to fit your case.

Q4: Do you offer custom labeling or white-label shipping?

Yes. We provide OEM packaging, patient ID labeling, and custom invoices for labs or distributors.

Q5: What if a denture doesn’t fit properly?

First, we review case inputs and model accuracy. If the issue is confirmed (e.g., misfit due to model defect or unclear border), we offer free remakes within our quality policy. Adjustment guides are also available.

Q6: Can I order bulk units for a school, nursing home, or public project?

Yes. We handle high-volume removable programs with pre-tagged labeling, color selection, and batch packaging. Contact us for a quote or demo set.

Q7: How can I communicate design preferences (tooth shape, shade, etc.)?

You can upload instructions, intraoral photos, shade tabs, and even bite scan notes with your order. For repeat doctors, we save preferences in our client system.

Q8: Do you support metal frameworks for partials?

Yes. We offer cobalt-chrome frameworks with digitally designed clasps and occlusal rests. We also verify opposing occlusion if files are provided.

Still have questions? Our removable case coordinators can walk you through your first few cases and ensure a smooth start.

The Future of PFM & Full Cast Restorations Isn’t Over — It’s Just Smarter

While zirconia and lithium disilicate dominate the headlines, porcelain-fused-to-metal and full-cast restorations still serve millions of patients worldwide. And they’re evolving, not vanishing.

🔍 1. Selective Use Over Replacement

Clinicians today are smarter in matching material to indication.

Full cast molars? Still unbeaten in bruxism cases.

PFM bridges? Often the safest call when span, cost, and shade all matter.

✅ Raytops Insight:

We help you mix materials within one digital workflow — full-cast posterior, PFM anterior, all on a single scan submission.

🧪 2. Alloy Engineering Is Improving

Modern semi-precious and high-noble alloys show better porcelain bonding, lower oxide staining, and improved biocompatibility — even in patients previously considered “metal-sensitive.”

✅ Raytops Insight:

We use CE/FDA-certified alloys with known oxide performance curves — reducing porcelain delamination and esthetic shade drift over time.

⚙️ 3. Digitization Brings New Life to Traditional Restorations

The fusion of CAD design, CNC milling of copings, and ceramic firing with digitally defined cutbacks brings unprecedented accuracy to even the most “manual” crown type.

✅ Raytops Insight:

Every PFM case we touch passes through a technician-verified CAD step — even if it starts with an analog impression.

🌍 4. Global Cost Pressures Favor Durable, Proven Options

In many public health systems, PFM and full-cast crowns remain reimbursable standards. For cost-sensitive markets, they offer the best ratio of longevity to spend.

✅ Raytops Insight:

We serve both premium cosmetic practices and national group contracts — with flexible alloy tiering per zone.

🧠 The Takeaway?

PFM isn’t outdated — it’s strategic.

Full Cast isn’t basic — it’s reliable.

The future isn’t always about new materials. It’s about using the right ones, the right way — and Raytops is here to help you do that.