Inconsistent restoration fit, unclear margins, and high remake rates are common issues for dental labs that still rely on analog workflows. As digital systems become more accessible, lab decision-makers are reevaluating how each step in their production chain—from scan intake to milling output—affects clinical outcomes and operational efficiency.

Digital workflows offer more than speed; they enable precision. From margin clarity in intraoral scans to automated alerts in CAD design and traceable outputs in CAM milling, each component helps reduce variability and prevent remakes before they occur. For labs under pressure to meet consistent quality expectations, understanding the technical checkpoints across a digital workflow is now essential.

Labs evaluating the ROI of digital workflows should focus on five key checkpoints:

- Input Quality

How accurate are scan files? Are margins well-defined from the start? - CAD Design

Is software-assisted margin detection and occlusal simulation in place? - CAM Production

Are 5-axis systems or calibrated printers used for tight tolerances? - Digital QA

Does the lab provide checkpoints, pre-milling validation, and deviation logs? - Outcome Metrics

What is the current remake rate? How has turnaround time improved?

Labs prepared with these digital capabilities can offer greater predictability, faster corrections, and stronger alignment with clinical teams—without overpromising or sacrificing precision.

What Are the Common Sources of Errors in Traditional Restoration Workflows?

Traditional dental workflows often accumulate small but compounding errors that remain hidden until the final restoration delivery. These issues primarily stem from analog impressions, manual model fabrication, and the lack of early-stage verification tools—making it harder to control marginal accuracy and fit quality.

Traditional-dental-lab-errors-impression-waxup

How do analog impressions affect margin clarity and fit accuracy?

Analog impressions are inherently prone to distortion, especially when moisture, patient movement, or delayed pouring affects the final cast.

- Material shrinkage and elasticity distortion: Silicone or polyether materials can shrink during setting or deform during removal, leading to unclear or rounded margin lines.

- Pouring delays create voids: The longer the time between impression and stone pouring, the higher the risk of expansion inaccuracies or bubble inclusions at critical edges.

- Single-use tray errors: Ill-fitting trays or insufficient retraction often compromise subgingival margin capture—causing undetected undercuts and fit gaps.

For restorations where sub-millimeter precision is essential, these analog artifacts can cause poor internal fit, premature contacts, or open margins—all of which may necessitate a costly remake.

🔗 Explore more on margin clarity challenges in analog workflows

What issues arise during manual model and wax-up fabrication?

The handcrafted nature of traditional wax-ups leaves too much room for interpretation, which can introduce variability even among skilled technicians.

- Hand carving inconsistencies: Wax thickness, contour anatomy, and contact areas are subject to each technician’s style, resulting in inconsistent occlusal contacts across cases.

- Stone model instability: Stone can chip or abrade during pin setting and trimming, affecting reference planes and contact points.

- Lack of precise calibration: Without digital baselines, minor asymmetries or angulation misreads often go undetected until seating or try-in.

Even in well-trained labs, manual steps add significant operator-dependent variables, leading to deviations from the clinician’s original intent.

Why are these errors often undetected until final delivery?

The traditional workflow lacks integrated checkpoints, so many issues are only discovered during the final try-in or delivery to the dentist.

- No early-stage verification: Without digital preview or fit simulation, there’s no way to test internal adaptation before production.

- Delayed discovery of margin issues: Margin inaccuracies from impressions or wax-ups aren’t visible until seating—when open margins or poor contact become evident.

- Lack of traceability: In manual systems, identifying the exact step where distortion occurred is difficult, making process improvement nearly impossible.

This delay not only increases remake rates but also disrupts clinical scheduling and erodes trust between lab and practice.

✅ Most restoration fit issues originate before the milling stage – TRUE

Inaccuracies usually arise during scanning, impression taking, or manual modeling—not in the CAM phase. Identifying these early ensures better final fit.

❌ Analog workflows allow full detection of margin gaps – FALSE

Without digital magnification or simulation, margin discrepancies often remain hidden until delivery, increasing the risk of remakes or clinical failure.

How Do Digital Scanning Methods Improve Accuracy Early in the Process?

Digital scanning improves restoration precision from the very beginning by minimizing impression distortion, capturing clearer margins, and enabling early-stage detection of fit-related risks. Whether through intraoral or model scanning, digital workflows set a more accurate foundation—reducing the likelihood of downstream remakes.

Intraoral-scanner-dental-lab-accuracy-comparison

What precision advantages exist between intraoral and model scanners?

Different types of scanners serve different purposes, but both surpass traditional methods in clarity and consistency. Here’s a comparison of their core precision metrics:

| Scanner Type | Accuracy (µm) | Use Case | Margin Detail Visibility | Operator Dependency |

|---|---|---|---|---|

| Intraoral Scanner | 10–20 µm | Direct patient scan, chairside | High | Medium |

| Desktop Model Scanner | 5–10 µm | Stone model or printed model scanning | Very High | Low |

Intraoral scanners capture real-time patient anatomy, ideal for single-unit or quadrant cases. Desktop scanners, when used on 3D-printed or poured models, provide even finer detail and greater control over scanning angles—making them more suitable for multi-unit or complex restorations.

How do digital scans reduce distortion compared to analog impressions?

Digital workflows eliminate several key sources of distortion that are inherent in physical impressions:

- No material shrinkage: Scanning bypasses silicone or polyether distortion risks, especially around deep margins.

- Environmental stability: Scans aren’t affected by temperature, humidity, or time delays between taking and processing.

- Consistent scanner behavior: Unlike human pouring or trimming, scanning is controlled by software, reducing variability.

- Repeatable and correctable: If a scan has a missed spot, it can be rescanned in real time—no need to retake a full impression.

These factors ensure a more reliable foundation for every restoration design and reduce the cascading impact of upstream errors.

Can digital inputs help detect margin gaps or undercuts pre-design?

Yes, digital scans enable the detection of margin-related issues before any design begins, allowing for early intervention:

- Automatic margin detection tools highlight incomplete or rounded edges, prompting retakes or refinement.

- Undercut visualization functions reveal inaccessible zones early, especially in bridge or splinted cases.

- Integrated color maps show deviation zones between scan and baseline, making discrepancies visible at a glance.

- Cross-section views help technicians assess tissue retraction, subgingival clearance, and parallelism even before the CAD step.

When used correctly, these tools allow labs to catch errors while still reversible, preventing the need for redesigns or re-fabrications later.

Key scanning platforms like 3Shape, Medit, and Exocad now offer native margin alerts and undercut flags, creating a more intelligent and preemptive workflow.

Digital scanning isn’t just about visualization—it’s about making intelligent, front-loaded decisions that minimize risk from day one.

Digital scanning technologies improve restoration precision by eliminating analog distortion, providing verifiable margin clarity, and enabling real-time feedback during scan acquisition. Labs that adopt these tools early in the workflow consistently report fewer remakes and better clinical integration.

How Does CAD Design Minimize Manual Errors and Improve Consistency?

CAD systems reduce variability and human error by converting manual design steps into software-guided, repeatable digital workflows. With embedded anatomical libraries, margin marking tools, and automated alerts, CAD platforms bring standardization and predictive control into the heart of prosthetic design.

Digital-cad-design-dental-software-anatomy-margin

What role do digital margin marking and anatomical libraries play?

Margin definition and morphology customization are core to CAD’s precision advantage.

- Auto-margin suggestion tools help reduce human misjudgment, especially on blurred or subgingival margins.

- Manual override with control points allows the technician to refine details when needed, maintaining adaptability.

- Anatomical libraries provide pre-designed tooth morphologies based on natural averages—ensuring functional and aesthetic standards across different technicians and cases.

- Custom presets can be created per clinic preference (e.g., occlusal depth, cusp slope), which enhances consistency across batches or recurring clients.

By embedding these features into the design process, CAD minimizes variations caused by hand-carved wax-ups or subjective technician interpretations.

🔗 Explore how digital crown libraries standardize morphology

How do CAD systems simulate occlusion and verify dynamic fit?

Occlusal dynamics are simulated in CAD using real-time adjustment features and multi-angle articulation tools. A typical digital occlusion verification includes:

- Scan alignment: Maxillary and mandibular arches are aligned using bite registrations.

- Virtual articulation: Simulates lateral and protrusive movements using adjustable parameters.

- Contact point mapping: Visualized using color-coded pressure indicators for high/low points.

- Auto-adjustment options: Excess contacts are trimmed digitally before milling or printing.

- Interarch clearance checks: Ensures minimum material thickness and eliminates hyperocclusion risk.

Compared to articulating paper in physical workflows, digital occlusion provides a repeatable and adjustable model that reduces chairside refinements and remakes.

Can software alerts proactively flag design inconsistencies?

Yes, modern CAD systems integrate real-time logic that flags design flaws before fabrication:

- Undercut detection: Highlights draw issues in bridge designs or clasp assemblies.

- Thin wall warning: Alerts when material thickness drops below lab-specified thresholds.

- Margin gap notification: Visual color alerts on missed or double margins.

- Anatomical collision flags: Warn of interference in pontic zones or abutment angles.

These checks reduce the burden on technician memory and catch issues early in the workflow, making designs safer and more predictable for milling or printing. Systems like Exocad and 3Shape routinely include customizable alert parameters that adapt to specific lab protocols.

🔗 Learn more about digital validation tools in CAD design

✅ CAD-based design often requires less technician adjustment – TRUE

With proper presets and client profiles, CAD output is more consistent than hand-waxed cases and typically requires fewer chairside corrections.

❌ Manual wax-ups offer better occlusal customization than CAD – FALSE

Digital articulation tools simulate dynamic occlusion more reliably and consistently than manual wax-ups, reducing human variability.

How Can CAM Milling or 3D Printing Deliver More Consistent Results?

CAM technologies enhance consistency and repeatability by translating digital designs into precisely controlled physical outputs. Unlike manual methods, milling and 3D printing follow fixed mechanical tolerances and traceable settings—significantly reducing variability in fit, contact, and margin integrity.

Dental-lab-CAM-milling-vs-handcraft-comparison

How do CAM machine tolerances compare to manual methods?

Digital manufacturing systems operate within strict mechanical tolerances that minimize human-induced variation. Here’s a comparison:

| Fabrication Method | Dimensional Tolerance | Repeatability | Operator Dependency | Risk of Micro-Gaps |

|---|---|---|---|---|

| 5-axis CAM Milling | ±20–30 µm | Very High | Low | Minimal |

| High-Res 3D Printing | ±40–70 µm | High | Medium | Low |

| Manual Wax-Up + Casting | ±100–150 µm | Variable | High | Higher |

Both CAM milling and resin printing ensure more uniform wall thickness, marginal integrity, and occlusal fit—particularly for multi-unit or splinted restorations.

🔗 Read more on CAM milling accuracy benchmarks

Why does layer resolution or toolpath affect restoration fit?

The accuracy of CAM output depends not just on machine type but also on setting choices made before execution:

- Layer resolution (3D printing): Thinner layers (e.g., 50 µm) provide smoother margins and finer anatomical detail, but increase build time.

- Toolpath strategies (milling): Spiral vs zig-zag paths affect how surface tension and sharp angles are rendered.

- Tool size and wear: Using a worn bur or incorrect tool diameter can cause chipping or dimensional drift at critical points.

- Material calibration: Different materials expand or shrink differently—pre-compensated settings ensure consistent output across materials.

Technicians who understand and manage these variables consistently produce restorations that require little or no chairside adjustment.

Can automated CAM logs track deviations for traceability?

Yes, CAM software offers traceability features that improve accountability and process validation:

- Auto-generated machining logs show which tools, offsets, and settings were used per case.

- Deviation reporting compares actual vs expected thickness and toolpath completion, flagging anomalies.

- Machine calibration history can be reviewed for wear tracking or error correlation.

- Batch management systems link each case to its design file, operator, and post-processing data.

These logs not only aid in internal QA audits but also strengthen confidence when labs need to justify consistency or defend against remake claims.

✅ Handmade crowns offer more individualized fit than CAM – FALSE

While hand skills offer adaptability, they introduce inconsistency. CAM ensures precision fit within microns of control.

❌ 3D printing doesn’t support predictable contact points – FALSE

High-res resin systems with calibrated settings can match or exceed contact point predictability compared to wax casting.

What Digital QA Mechanisms Help Prevent Remakes Before Delivery?

Digital QA mechanisms build multiple checkpoints into the production cycle, allowing labs to proactively catch and correct issues before restorations are shipped. From scan validation to final fit simulation, integrated digital tools create a continuous quality loop that lowers remake rates and builds client trust.

Digital-dental-QA-workflow-multi-checkpoints

Where are the checkpoints between scan, CAD, and CAM?

A strong digital QA process includes verifications at multiple stages of the workflow:

- Scan Stage QA: Verify complete data capture, margin visibility, and absence of artifacts using software overlays.

- CAD QA: Check margin alignment, contact strength, anatomical accuracy, and occlusal clearance before exporting.

- CAM QA: Simulate toolpaths and check thickness compliance, then review milling/printing logs after fabrication.

- Post-Processing QA: Visually inspect restorations for smoothness, edge integrity, and fit verification with printed models or virtual try-ins.

Each of these checkpoints minimizes the chance of defects reaching the delivery box—and creates an audit trail that improves transparency and accountability.

How does margin verification or fit simulation reduce late-stage errors?

Late-stage remakes are often due to undetected discrepancies in margin capture or internal fit. Digital tools offer early detection:

- Margin gap visualization shows colored alerts when margins are incomplete or irregular.

- Virtual seating simulations preview restoration insertion and identify contact interferences or rocking movement.

- Cross-sectional slicing allows precise measurement of wall thickness and cement space in critical areas.

- Automated contact reports grade proximal and occlusal points by pressure level, ensuring balance.

These tools eliminate guesswork and allow labs to intervene while issues are still reversible—saving time and preserving client confidence.

🔗 See examples in digital restoration verification workflows

Can digital traceability improve audit trails and continuous feedback?

Yes, traceability tools close the QA loop and support continuous improvement:

- Case tracking dashboards link each STL to QA logs, operator ID, and machine ID.

- Deviation reports log when output falls outside preset norms—useful for operator coaching or material tuning.

- Client-side feedback integration allows dentists to report marginal issues, which link back to original design files.

- Cycle-time analytics help labs identify bottlenecks or recurring issues for workflow optimization.

This ecosystem builds a learning loop around quality, enabling labs to evolve proactively rather than reactively.

Digital QA is no longer optional—it’s an essential pillar of scalable, low-defect dental production. Labs that implement these mechanisms consistently outperform those relying on manual spot-checks alone.

What Quantifiable Benefits Can Labs Expect From Digital Workflows?

Adopting a fully digital workflow enables dental labs to reduce remake rates, shorten turnaround times, and improve consistency in fit and accuracy. These gains are not abstract—they’re measurable across thousands of cases and verified through internal audits and external feedback.

Dental-lab-digital-vs-analog-performance-metrics

How much can remake rates be reduced with full digital adoption?

Labs that migrate to digital workflows consistently report a drop in remake rates due to better margin clarity, earlier error detection, and tighter production control.

- 25–50% reduction in remake rates is commonly reported in CAD/CAM labs, especially when combining intraoral scans with design validation tools.

- Main contributors to remake reduction include digital margin verification, fit simulation, and automated contact checks.

- Consistency across technicians improves as software standardizes design parameters, reducing subjective interpretation.

Many labs report remake rates dropping from 8–10% to under 4%, especially when paired with dentist education and pre-case file checks.

What are typical turnaround time improvements across workflows?

Speed gains are another major benefit, as digital workflows remove analog delays related to setting, pouring, and shipping.

| Workflow Stage | Analog Time (avg) | Digital Time (avg) | Efficiency Gain |

|---|---|---|---|

| Impression & Model | 1.5–2 days | 0.5 day (same-day scan) | ~60–75% faster |

| Wax-Up & Design | 1 day | 2–4 hours | ~50% faster |

| Milling/Printing | 0.5–1 day | 4–6 hours | ~30–40% faster |

| Total Turnaround | 5–7 days | 2.5–3.5 days | ~50% reduction |

For high-volume clients, this improvement reduces patient wait times and improves clinic scheduling efficiency.

What accuracy benchmarks do high-performing labs usually report?

Accuracy isn’t just about feeling—it’s about measurable fit.

- Internal fit tolerance of ≤40 µm is considered best practice in milled zirconia restorations.

- Contact point precision within ±50 µm ensures minimal chairside adjustments.

- Margin fidelity rated “clinically acceptable” in 95%+ of cases when verified digitally pre-CAM.

- Consistent inter-arch clearance within preset cement gap ranges (80–120 µm) avoids over-tight fits or rocking.

These benchmarks allow labs to align with global standards while building trust through performance reporting.

Digital workflows empower labs with measurable gains in accuracy, turnaround, and client satisfaction. Teams that track and report these metrics position themselves as reliable long-term partners.

What Should You Ask to Assess a Lab’s Digital Precision and QA Process?

When selecting a dental lab for long-term collaboration, asking the right questions about digital QA and precision protocols is essential. These questions help distinguish between labs that simply “own digital tools” versus those that fully embed digital validation into their workflow.

Dental-client-evaluating-lab-digital-process-questions

Do you perform digital fit simulation before milling?

Key questions to ask your lab about pre-fabrication validation include:

- Can you simulate virtual seating and check for interferences before CAM?

- Is occlusal contact digitally graded and adjusted before sending to mill?

- Do you run undercut detection and margin line confirmation inside the CAD?

- What software or platform is used for these simulations (e.g., Exocad, 3Shape)?

Labs that can confidently answer these questions are far more likely to deliver restorations with predictable fit.

Can you provide real-time feedback or QA logs during trial cases?

Trial orders or sample batches are excellent opportunities to evaluate how well a lab documents and shares its internal QA process:

- Do they offer annotated screenshots of fit verification?

- Is there a shared folder or dashboard with production logs?

- Do they explain how remake risks were prevented—not just claim low remake rates?

- Can they link QA steps to specific digital checkpoints in your sample?

When labs make this process visible, clients gain trust and feel more confident scaling orders.

Are margin/fit validation reports standard in your delivery?

Here’s a simple process to confirm whether the lab uses standard QA documentation:

- Check if margin screenshots are attached to the final STL or PDF report.

- Ask whether fit reports include color-coded gap maps or pressure indicators.

- Confirm that the QA document is traceable to technician ID and date.

- Ensure the reports are available for trial and regular production—not only on request.

This level of transparency is increasingly expected, especially by DSOs and procurement-led clinics.

✅ A well-documented digital workflow should include occlusion simulation – TRUE

High-performing labs often run occlusal checks before production to prevent adjustment issues and ensure clinical fit.

❌ Receiving a low remake rate claim is enough to confirm QA – FALSE

Verbal remake rates without documented logs are not reliable proof of consistent quality assurance.

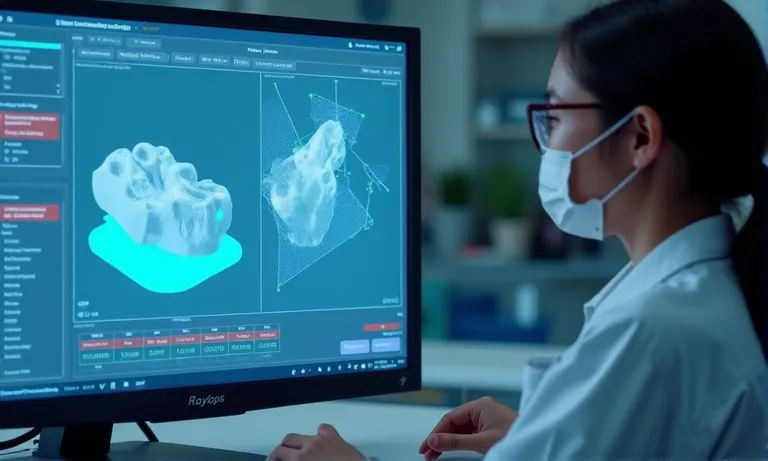

How Does Raytops Support Clients in Ensuring Restoration Accuracy?

As a global dental lab partner, Raytops integrates digital checkpoints and collaborative QA practices to support clinics, DSOs, and labs in achieving precise, predictable restorations. Rather than imposing protocols, we embed into our clients’ systems—helping them meet quality goals through reliable digital coordination.

Raytops-digital-dental-lab-restoration-accuracy-checkpoints

STL file pre-check, margin alert, and design flagging

Before design begins, Raytops applies a series of automated and human checks to submitted STL files:

- Margin line clarity assessment using CAD-native tools to confirm clean visibility and subgingival exposure.

- Auto-detection of artifacts, holes, or double scans that might impact fit or design symmetry.

- Design flag feedback loop: If margin issues or draw path problems are detected, we notify clients for re-scan or digital correction before proceeding.

These early-stage interventions dramatically reduce wasted design cycles and misfit-related remakes.

Fit preview confirmation before CAM

Our pre-CAM process includes technician-guided verification of design intent and CAM feasibility:

- Digital insertion simulation to assess fit resistance and contact pressure.

- Automated wall thickness check to ensure material safety in production.

- Final technician approval before nesting or printing—serving as the last digital gate before physical output.

This approach blends automation with experienced review, minimizing CAM-stage surprises and physical inconsistencies.

Final scan validation and performance feedback documentation

Every completed case at Raytops is subject to final-stage QA validation before shipping:

- Post-fabrication 3D scan comparison against the original STL to verify margin fidelity and contact match.

- Fit summary sheet or screenshot included for high-value or trial cases.

- Batch traceability logs maintained for audit requests or continuous improvement review.

Clients can request performance summaries on a case or weekly basis—especially useful for DSO procurement teams tracking vendor performance across locations.

Raytops doesn’t replace clinical decision-making—we support it through reliable, scalable digital execution.

By combining upstream prevention, midstream simulation, and downstream validation, Raytops helps global clients reduce remake rates, shorten turnaround, and deliver consistent clinical outcomes across restorations.

Conclusion: Digital Workflows Are Precision Enablers—When Backed by the Right Lab

Digital workflows alone don’t guarantee fewer remakes or better restorations—but when combined with disciplined QA, intelligent checkpoints, and reliable lab execution, they become a powerful enabler of consistency, speed, and clinical success.

From eliminating analog distortion to simulating real-time occlusion, each digital stage offers opportunities to detect errors early and deliver restorations that fit right the first time. The benefits are measurable: lower remake rates, shorter turnaround times, and tighter control over margin and contact fidelity.

However, realizing these benefits depends on how well your lab supports the process—not just with software, but with insight, accountability, and operational discipline.

At Raytops, we work alongside clinics, DSOs, and global dental labs to turn digital workflows into dependable clinical results. By embedding validation tools, proactive communication, and post-fabrication feedback into every case, we help clients reduce variability and scale with confidence.

Digital accuracy isn’t just a toolset—it’s a mindset, backed by a lab that knows how to use it.