Removables Dental Lab

- 10+ years experience for China dental lab outsourcing services

- Processing 10,000 dental cases each month

- 4 days Turnround time

- 5 years warranty support

Raytops Removable Dental

Removables dental refers to custom-made dental prosthetics, such as partial and full dentures, designed to restore missing teeth. These devices are easy to remove and clean, offering a cost-effective and comfortable solution for improving oral function and appearance. Options include flexible dentures, known for their comfort, and traditional acrylic or metal frameworks for durability. Commonly chosen by patients seeking non-invasive tooth replacement, removables dental products are ideal for those prioritizing convenience and affordability. For high-quality, custom-fit solutions, consult a professional dental lab or manufacturer specializing in removable prosthetics.

Featured Crowns & Bridge Dental

Acrylic Dentures

Durable, tissue-supported full-arch prosthetics made for long-term edentulous cases.

Use Case:

Complete arch tooth loss; conventional or immediate full denturesKey Benefit:

High wear resistance, stable fit, and cost-effective restorationRecommended For:

General practices, DSO clinics, and elder-care institutions managing edentulous patients

Flexible Partials Dental

Durable, tissue-supported full-arch prosthetics made for long-term edentulous cases.

Use Case:

Complete arch tooth loss; conventional or immediate full denturesKey Benefit:

High wear resistance, stable fit, and cost-effective restorationRecommended For:

General practices, DSO clinics, and elder-care institutions managing edentulous patients

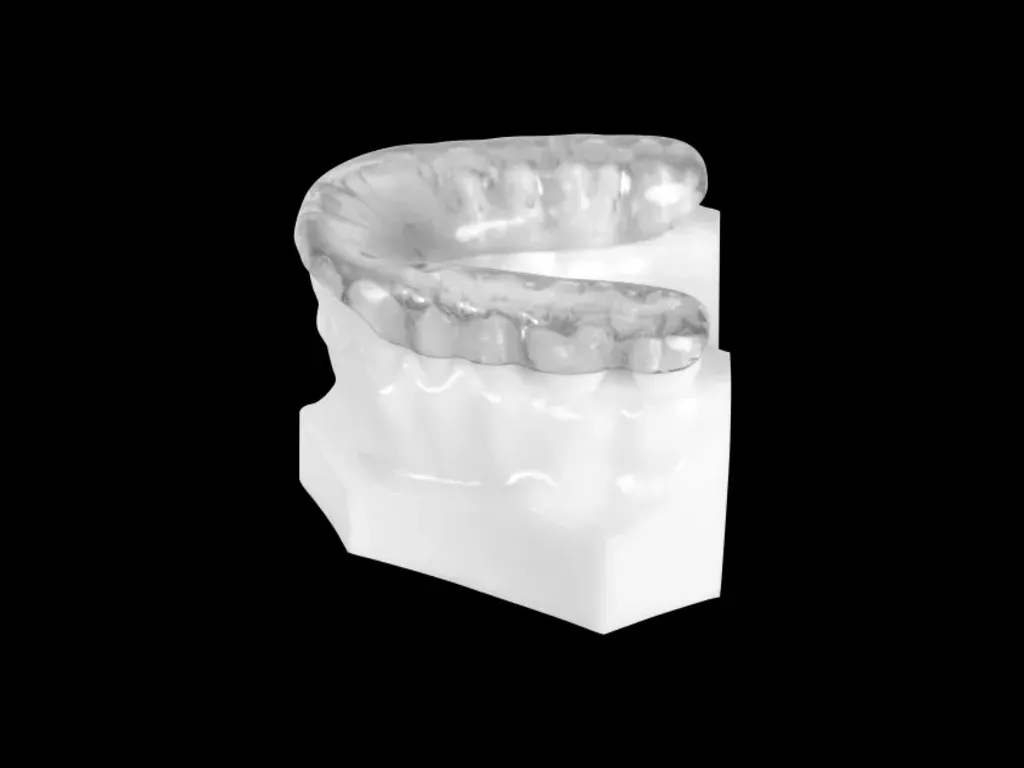

Night Guard

Custom-made occlusal appliances for managing bruxism, clenching.

Use Case:

Night-time occlusal protection for patients with grinding or muscle fatigue symptomsKey Benefit:

Accurate occlusion fit, soft-to-hard dual-layer options for patient comfortRecommended For:

General dentists, orthodontists, and sleep-focused dental clinics

Sports Dental Guards

Impact-absorbing, multilayered mouthguards customized to fit dentition.

Use Case:

Contact sports or high-impact physical activity where dental protection is essentialKey Benefit:

Secure retention, flexible design, and breathable for active useRecommended For:

Pediatric and general clinics, school athletic programs, dental distributors

Removable Dental Appliances Made for Real-World Comfort and Precision

Comprehensive Implant Restoration Solutions — From Single Units to Full Arches

At Raytops Dental Lab, we specialize in the precise fabrication of implant-supported restorations, built to meet the functional, esthetic, and prosthetic requirements of modern implant dentistry.

Whether you’re placing a single-unit screw-retained crown or planning a full-arch hybrid bridge, we deliver restorations that integrate seamlessly with your workflow and deliver confidence at chairside.

Our full implant line includes:

Screw-retained crowns and bridges for predictable retrievability

Custom titanium abutments for soft tissue management and angulation control

Full-contour zirconia bridges for high-strength, esthetic full-arch cases

Titanium hybrid dentures for fixed-removable rehabilitations

Snap-on and Locator-based overdentures for affordability and patient comfort

✅ Why Dental Professionals Choose Raytops for Implant Cases

✔️ Digital-Ready Workflows — Accepting all major intraoral scans and guided surgery outputs

✔️ Proven Compatibility — Abutments and interfaces compatible with major implant systems

✔️ High First-Time Fit Rate — Minimizing chairside adjustments and patient returns

✔️ Full-Arch Expertise — Experience handling complex, multi-unit restorations

✔️ Collaborative Support — Clear case communication, optional design guidance, fast feedback

Whether you’re a clinician restoring implants or a lab outsourcing overflow, Raytops is your dependable partner for implant cases that demand more than just good looks.

Material Types & Comparison

Choosing the Right Material for Removable Appliances

Removable restorations and guards rely heavily on the right material combination — not just for longevity, but for comfort, retention, and daily use experience. Raytops offers a range of certified, lab-tested materials to match every patient need and clinical scenario.

📊 Material Comparison Table

| Material Type | Flexibility | Strength | Esthetics | Indications |

|---|---|---|---|---|

| High-Impact Acrylic | ★★☆☆☆ | ★★★★☆ | ★★★☆☆ | Full dentures, partials, budget-friendly |

| Valplast® (Nylon) | ★★★★★ | ★★☆☆☆ | ★★★★☆ | Flexible partials, esthetic anterior use |

| Cobalt-Chrome (Metal) | ★☆☆☆☆ | ★★★★★ | ★★☆☆☆ | Rigid partials, long-span frameworks |

| Dual-Layer EVA/PU | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | Night guards for bruxism and light TMJ |

| Triple-Layer EVA | ★★★☆☆ | ★★☆☆☆ | ★★★☆☆ | Sports dental guards, athletic use |

🧠 How to Match Material to Clinical Need

Need maximum fracture resistance for full dentures?

→ Choose high-impact acrylic for durability and repairabilityWant better flexibility and esthetics in a partial?

→ Go with Valplast® flexible base for comfort and soft tissue blendingWorking with posterior load or long-span framework?

→ Cobalt-Chrome cast partials offer rigid support and longevityMaking a dual-purpose night guard?

→ Use dual-layer (soft-hard) PU guards for comfort and functional occlusion controlProtecting teeth during sports?

→ Multilayer EVA guards provide impact protection and breathability

✅ Raytops Material Standards

CE- and FDA-approved PMMA and flexible resins

Japanese cobalt-chrome alloy for precision-cast frameworks

Biocompatibility testing (ISO 10993) for all intraoral appliances

Color customization options for guards (clear, blue, green, black, etc.)

Not sure which material is right for your removable case? Our team can review your case file and recommend the best combination based on age, arch, and intended usage time.

Dental lab Digital Workflow

Digital When It Helps. Traditional When It’s Better.

Not all removable appliances are ready for full-digitization — but at Raytops, we combine the best of both worlds. Whether you work with intraoral scanners or traditional impressions, we ensure accurate fit, functional occlusion, and smooth delivery with each case.

🧩 Our Production Workflow for Removables

1️⃣ Case Intake & File Compatibility

Accepting digital scans (STL) from iTero, Medit, TRIOS, Carestream, and others

Traditional impressions (PVS, alginate) also accepted with stone model or via model pouring service

Clients may include bite registrations, try-in feedback, or shade guides

2️⃣ Digital Model Processing & CAD Design

For guards & partials: STL models aligned for occlusal calibration

For dentures: digital baseplate and tooth setup via 3Shape Dental System

Try-in preview images available upon request

Optional: scan and digitization of physical wax-ups

3️⃣ CAM Fabrication & Finishing

Night guards & sports guards: 3D-printed or pressure-formed on digitally trimmed models

Acrylic dentures & partials: Milled or flask-packed with hand-layered acrylic (based on case type)

Cast metal partials: Wax-up digitally designed, cast in Japanese Co-Cr alloy, then finished manually

4️⃣ QC & Delivery

Fit check on printed models or physical duplicates

Occlusal surfaces polished to minimize chairside adjustment

Final appliances labeled per client specs (e.g. patient ID, arch, color)

International shipping with protective, moisture-sealed packaging

✅ What This Means for You

Reduced chairside adjustment

Fewer reworks from poor retention or high occlusion

Compatible with your scanner — or no scanner at all

Seamless integration of lab and clinic communication

Predictable turnaround: 4–6 working days for most cases

Whether you’re sending a scan or a stone model, we design removables with clinical reality in mind — and deliver with consistency.

Customization - Product Fits Reference

Tailored to Patient Anatomy, Function, and Preference

Each removable case is different. At Raytops, customization is standard — not an extra. From tooth shade to occlusal thickness, we fine-tune each appliance based on your instructions and patient expectations.

Whether you’re working on a full-arch denture or a high-wear night guard, our technicians are trained to interpret clinical intent and deliver accordingly.

🦷 For Dentures & Partials

Tooth Selection & Arrangement

Based on age, arch form, occlusion, esthetic request (e.g. flat, youthful, gender-based setups)Shade Matching

A1–D4 or vita 3D shades supported, with custom gingival tinting (if requested)Base Contour & Border Molding

Adjusted for comfort and retention, based on scan/model dataTry-In Options

Digital try-in previews or physical wax-up upon requestPatient Labeling

Name/ID embedded in base (optional, for institutions or group practices)

😬 For Night Guards & Sports Guards

Thickness Control

Selectable occlusal thickness (1.5 mm – 4 mm), variable layering based on parafunctional diagnosisMaterial Hardness

Soft (EVA), Hard (PU), Dual-layer options customized for bruxism levelArch Coverage

Full upper, lower, or horseshoe shape — adjustable per appliance typeColor Preferences

Clear, white, blue, black, or school/team colors (for sports guards)Engraving / Personalization

Embedded initials or team name in colored guards (optional)

🤝 How We Support Your Design Intent

You can upload smile photos, bite scan files, or design notes with the order

If unclear, we contact you before fabrication

For recurring preferences (e.g. “Dr. A prefers B2, tight flange”), we keep digital records per clinic/lab

Clinical Applications & Indications

Designed for the Demands of Daily Practice

From full dentures to occlusal splints, Raytops removable appliances are tailored for clinical reliability. We focus on first-time fit, functional adaptation, and minimal adjustment — so you can spend less time chairside and more time with your patients.

🔍 Common Clinical Use Cases We Support

| Clinical Scenario | Recommended Product(s) |

|---|---|

| Complete edentulous patient | Acrylic full denture |

| Selective tooth loss in posterior arch | Cast metal or flexible partial denture |

| Young athlete with contact sport activity | Sports dental guard (custom color/fit) |

| Bruxism with joint discomfort (TMJ) | Dual-layer night guard (soft inside) |

| Immediate denture post-extraction | Economy acrylic denture with quick setup |

| Geriatric patient with shallow ridges | Custom border-molded denture base |

| Institutional patient labeling required | ID-embedded acrylic base option |

🤝 How We Collaborate on Removable Cases

Input We Accept:

Digital scans (STL), analog impressions, bite registrations, wax-up, try-in photosCommunication Touchpoints:

We’ll clarify border extension, shade preferences, or material selection before fabrication if neededSpecial Case Handling:

For geriatric, pediatric, or repeat appliance patients — we adjust flange thickness, occlusal clearance, and soft tissue tolerance accordinglyPost-Delivery Support:

Minor modifications available with photo guidance or model returns; remake protocols in place for base misfit or pressure point issues

🧠 Technician Insight:

“For night guards, we often see cases where digital bite scans help us adjust the occlusion zones proactively — especially in TMJ-sensitive patients. With proper input, we can deliver a splint that seats cleanly with no need for in-chair grinding.”

Whether you’re restoring full arches or protecting teeth overnight, we ensure each appliance is not only fabricated right — but fits your patient’s real clinical needs.

🧠 How We Collaborate on Complex Cases

Implant Positioning & Access

We adapt screw access path or customize abutment angulation for ideal prosthetic placement.Soft Tissue Management

We design emergence profiles to shape the peri-implant tissue zone and ensure a natural-looking transition.Occlusion & Force Distribution

For full-arch and long-span restorations, we calibrate occlusal design and connector strength to distribute load effectively.Esthetic Harmony

Color matching, gingiva layering (if needed), and symmetry correction are coordinated in advance.Documentation & Input Flexibility

We accept STL, DICOM, bite scan files, photos, and even diagnostic wax-ups to align on case planning.

📦 Packaging for Real Practice Needs

DSOs can batch multiple single-unit cases

Labs can outsource overflow for full-arch zirconia or titanium hybrid workflows

Clinics receive fully pre-assembled screw-retained units (if requested) for chairside efficiency

Product & Material Selection Guide

Removable Restoration Selector – Find the Right Fit

Choosing the right removable appliance doesn’t have to be complicated. Use this guide to identify which product and material combination is best suited for your clinical case.

📊 Quick Product Comparison Table

| Product Type | Indicated For | Retention Style | Esthetics | Durability |

|---|---|---|---|---|

| Acrylic Full Denture | Full arch tooth loss, cost-conscious cases | Tissue-supported | ★★★☆☆ | ★★★★☆ |

| Cast Partial Denture | Multiple missing teeth with good abutments | Tooth-supported w/ clasp | ★★☆☆☆ | ★★★★★ |

| Flexible Partial | Esthetic zones, patients avoiding metal | Tissue and tooth-adapted | ★★★★☆ | ★★☆☆☆ |

| Night Guard | Bruxism, TMJ discomfort | Custom occlusal fit | — | ★★★★☆ |

| Sports Guard | Contact sports, impact risk | Suction + soft base | Color-custom | ★★★☆☆ |

🧪 Material Selection by Clinical Priority

| Clinical Need | Best Material Type | Why |

|---|---|---|

| Full-arch with high fracture risk | High-impact acrylic | Crack-resistant and repairable |

| Anterior esthetic zone partial | Valplast® flexible nylon | Natural translucency, no metal clasps |

| Strong occlusal forces (bruxism) | Dual-layer PU night guard | Comfort inside, hard outer surface |

| Pediatric or athletic protection | EVA triple-layer sports guard | Breathable, impact-absorbing |

| Institutional ID or patient marking | Engraved acrylic denture base | Embedded name or ID tag |

✅ Selection Tips from Our Lab

If esthetics > durability? → Flexible partials

If longevity > flexibility? → Cast metal frameworks

If patient has TMJ symptoms? → Use soft-hard night guard, 2.5mm or thicker

If post-extraction immediate use? → Recommend economy acrylic denture, modifiable base

If you serve nursing homes or school clinics? → Ask us about high-volume removable programs

Still unsure which appliance suits your case? Our technician team can help evaluate your scans or models and recommend the best configuration.

Why Partner with Raytops for Removable Solutions

Built for Predictable Comfort, Delivered with Technical Precision

Removable restorations are often underestimated — until they don’t fit. At Raytops, we take a technician-first approach to every denture, partial, and appliance we deliver. That means understanding the clinical context, reading the inputs properly, and communicating clearly when needed.

Our goal is simple: reduce chairside time, improve patient comfort, and make your workflow smoother.

🧩 Why Clinics and Labs Choose Raytops for Removables

🎯 High First-Fit Success Rate

Custom base contouring and occlusal calibration reduce post-seating adjustments

Soft tissue modeling refined with years of analog + digital case experience

Over 94% of denture cases require no significant chairside reline

🔄 Traditional & Digital Compatibility

Accept both intraoral scan workflows and conventional impressions

STL, stone models, bite registrations — all integrated seamlessly

In-house scanning of analog cases for digital design advantage

⚙️ Material Control & Custom Options

FDA/CE-certified PMMA, nylon, and EVA materials

Multicolor, thickness, and label customization (ideal for group practices, OEM models)

Predefined comfort preferences can be stored per doctor or lab client

🕒 Reliable Turnaround, Global Support

4–6 working days for most denture, partial, and guard cases

Optional OEM packaging for labs and distributors

Customer support in English, Mandarin, and dedicated case coordinators for volume clients

🧠 Smart Collaboration, Not Just Fulfillment

Real technician feedback for unclear borders, bites, or anatomical concerns

Recommendations for special cases: shallow ridges, reline patients, pediatric guards

Technician previews and try-in photos available on request

📌 Summary:

✅ 4 removable product lines

✅ 30+ export countries

✅ 94%+ first-fit rate

✅ Full customization support

✅ Clinic, DSO & lab partnerships across 3 continents

At Raytops, removable prosthetics are not “just basic work.” They’re a critical part of daily practice — and we treat them with the same precision as crowns and implants.

Real Cases. Real Results.

How We Help Clients Deliver Better Removable Results

📍 Case 1: DSO Group in the U.S. Standardizes Immediate Denture Workflow

The challenge:

A multi-location DSO needed consistent delivery of immediate full dentures post-extraction, but was struggling with variable base fit and slow case turnaround from local labs.

Our solution:

Raytops helped them switch to a pre-defined intake protocol, combining analog impressions with STL-converted base scanning. Try-in steps were optimized for speed and post-seating comfort.

Outcome:

40% reduction in seating time

100% on-time delivery over a 3-month pilot

Expanded partnership to partials and night guards

📍 Case 2: European Lab Solves Flexible Partial Remake Spike

The challenge:

A mid-size lab in Spain had a high remake rate on Valplast® partials due to inconsistent material control and communication gaps from their offshore supplier.

Our solution:

We introduced a shared case form with occlusal/esthetic notes and sent verified fit check photos before finalizing. Material batch traceability and consistent polishing were ensured.

Outcome:

Remake rate dropped from 12% to 2.5% in 6 weeks

Client began outsourcing all night guards and full acrylics to Raytops

Now handles white-label production for multiple clinics under their own brand

📍 Case 3: Sports Guard Program for a U.K. School Dental Network

The challenge:

A public-private school dental provider needed bulk orders of sports mouthguards in team colors, each with student initials, under strict time windows at semester start.

Our solution:

We implemented a bulk-order upload template, pre-sorted labeling, and sent visual previews of guard colors and thickness by group.

Outcome:

Delivered 180+ units in 2 batches across 3 weeks

All units labeled and individually packed

Renewed contract for 2 consecutive academic years

💬 What Our Partners Say

🗨️ “It’s not just that the dentures fit better — it’s that Raytops understands our intake challenges and responds fast when we need clarifications.”

— Clinical Director, U.S. DSO

🗨️ “For the first time, we don’t worry if a flexible partial will come back usable. The team checks details we didn’t expect a lab overseas to catch.”

— Lab Manager, Spain

🗨️ “We’ve tested multiple overseas suppliers. Raytops was the first to deliver guards on time, in color, labeled, and without last-minute excuses.”

— Program Coordinator, UK Dental School Network

Certifications & Regulatory Assurance

Removable Products You Can Import with Confidence

Raytops removable appliances are manufactured under strict quality control systems using internationally certified materials. Whether you’re a clinic, lab, or distributor, we provide the necessary documents to support your local compliance and import clearance.

✅ Certifications & Quality Documentation

| Certification / Document | What It Covers |

|---|---|

| ISO 13485:2016 | Medical device manufacturing quality management |

| FDA Registration (U.S.) | Manufacturer of removable dental appliances |

| CE Declaration of Conformity | Approved for intraoral use in EU |

| Biocompatibility Reports (ISO 10993) | PMMA, nylon, EVA, and night guard materials |

| Material Safety Data Sheets (MSDS) | Available for all denture bases and guard materials |

| Batch Certificates | Provided on request (acrylic, Valplast®, EVA) |

| Certificate of Origin / Form A | For customs and import duty purposes |

| OEM Labeling Compliance Support | Branding, packaging, documentation as per client need |

🧪 Material Transparency & Safety

Acrylic Dentures & Partials: High-impact PMMA from Japan and Korea

Flexible Bases: Original Valplast® and biocompatible equivalents

Night / Sports Guards: EVA, PU, and multilayer thermoplastics tested for intraoral use

Traceable material IDs for every production batch

🌍 Export-Friendly Documentation

We export to over 30 countries and can pre-package documentation sets for:

Private clinics

DSO networks

Public health institutions

OEM labs

Importers/distributors

Just let us know your local authority’s requirements — we’re ready.

When you outsource to Raytops, you’re not just getting a product — you’re getting documentation-ready, globally compliant dental devices.

Frequently Asked Questions

✅ Certifications & Quality Documentation

| Certification / Document | What It Covers |

|---|---|

| ISO 13485:2016 | Medical device manufacturing quality management |

| FDA Registration (U.S.) | Manufacturer of removable dental appliances |

| CE Declaration of Conformity | Approved for intraoral use in EU |

| Biocompatibility Reports (ISO 10993) | PMMA, nylon, EVA, and night guard materials |

| Material Safety Data Sheets (MSDS) | Available for all denture bases and guard materials |

| Batch Certificates | Provided on request (acrylic, Valplast®, EVA) |

| Certificate of Origin / Form A | For customs and import duty purposes |

| OEM Labeling Compliance Support | Branding, packaging, documentation as per client need |

🧪 Material Transparency & Safety

Acrylic Dentures & Partials: High-impact PMMA from Japan and Korea

Flexible Bases: Original Valplast® and biocompatible equivalents

Night / Sports Guards: EVA, PU, and multilayer thermoplastics tested for intraoral use

Traceable material IDs for every production batch

🌍 Export-Friendly Documentation

We export to over 30 countries and can pre-package documentation sets for:

Private clinics

DSO networks

Public health institutions

OEM labs

Importers/distributors

Just let us know your local authority’s requirements — we’re ready.

When you outsource to Raytops, you’re not just getting a product — you’re getting documentation-ready, globally compliant dental devices.

Q1: Can I send intraoral scan data for dentures or guards?

Yes. We accept STL files from all major scanners. For dentures, we also support digital setups based on scanned wax-ups or try-ins. Night guards and sports guards can be made fully from scan.

Q2: What’s your turnaround time for removable appliances?

Acrylic dentures or partials: 4–6 working days

Flexible partials: 5–6 working days

Night guards & sports guards: 3–5 working days

Shipping times vary by region (typically 2–5 days via DHL, UPS, or FedEx).

Q3: Can I combine analog and digital materials in one case?

Absolutely. Many clients send a stone model for the denture and a scan for the opposing. We adapt the workflow to fit your case.

Q4: Do you offer custom labeling or white-label shipping?

Yes. We provide OEM packaging, patient ID labeling, and custom invoices for labs or distributors.

Q5: What if a denture doesn’t fit properly?

First, we review case inputs and model accuracy. If the issue is confirmed (e.g., misfit due to model defect or unclear border), we offer free remakes within our quality policy. Adjustment guides are also available.

Q6: Can I order bulk units for a school, nursing home, or public project?

Yes. We handle high-volume removable programs with pre-tagged labeling, color selection, and batch packaging. Contact us for a quote or demo set.

Q7: How can I communicate design preferences (tooth shape, shade, etc.)?

You can upload instructions, intraoral photos, shade tabs, and even bite scan notes with your order. For repeat doctors, we save preferences in our client system.

Q8: Do you support metal frameworks for partials?

Yes. We offer cobalt-chrome frameworks with digitally designed clasps and occlusal rests. We also verify opposing occlusion if files are provided.

Still have questions? Our removable case coordinators can walk you through your first few cases and ensure a smooth start.

Trends & Future Outlook in Implant Restorations

Where Removables Are Headed – and How We’re Ready

The world of removable dental appliances is evolving fast — from new materials and 3D workflows to hyper-personalized patient designs. At Raytops, we stay ahead by combining proven craftsmanship with forward-looking processes.

🔍 1. Digital Denture Workflows Are Becoming the Norm

More clinics and labs are moving from analog impressions to full digital setups, including scan-based try-ins, baseplate simulation, and AI-assisted tooth positioning.

✅ Raytops Insight:

We accept full digital files (STL + bite scan), and provide virtual try-in previews for full dentures and guards.

🧪 2. Material Innovation Focused on Comfort & Biocompatibility

Materials like flexible nylon, multilayer thermoplastics, and impact-resistant PMMA are replacing older bulk acrylics — improving fracture resistance and long-term tissue tolerance.

✅ Raytops Insight:

We work with CE- and FDA-listed PMMA and Valplast®-class flexible bases, with batch-level traceability.

🧠 3. Personalization Beyond Shade — Toward Functional Design

Custom gingival tints, smile line design, personalized ID tags, and sport/team colors for guards are now common — especially in institutional and high-demand patient groups.

✅ Raytops Insight:

We offer ID-embedded dentures, color-coded sports guards, and multi-shade customization for all guard types.

🌐 4. Global Outsourcing Demands OEM-Ready Partners

As more DSOs and labs outsource for scale, there’s rising demand for white-label-ready, digitally fluent labs that can handle documentation, bulk packaging, and fast response support.

✅ Raytops Insight:

We ship to 30+ countries with OEM labeling, institutional packaging, and compliance kits for customs and regulation.

📈 Final Thought:

The next generation of removables will be:

🟢 Digital by design

🟢 Customized for the patient

🟢 Logistically integrated with your practice or labRaytops is built to support that transition — today and tomorrow.