Zirconia porcelain crown prices can vary dramatically, leaving clinics uncertain about what they’re really paying for.

Overlooking key cost drivers—like material grade, customization, or hidden service terms—can lead to budget overruns or unsatisfactory results.

By understanding what goes into crown pricing, dental teams can make value-based decisions that balance esthetics, performance, and reliability.

Pricing depends on zirconia type, layering complexity, CAD/CAM usage, technician time, lab location, turnaround speed, and warranty terms. Higher esthetic demands and faster delivery raise costs, while transparent service structures help clinics assess true value beyond unit price.

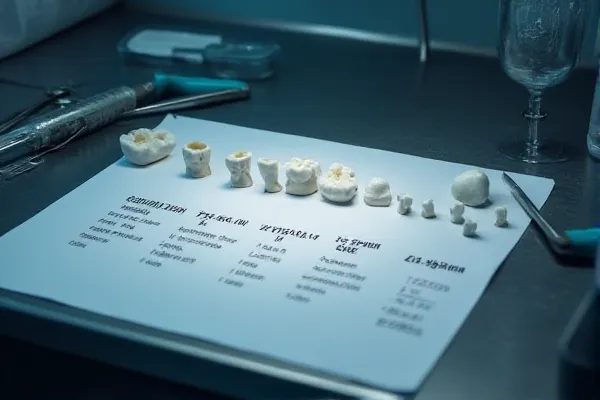

What Are the Core Cost Components of Zirconia Porcelain Crowns?

Understanding what drives the price of zirconia porcelain crowns helps clinics and procurement teams assess quotations accurately and avoid price-performance mismatches. Crown pricing isn’t arbitrary—it reflects a series of material, labor, and technology-based decisions made in the lab.

Zirconia-Crown-Cost-Structure

How Do Zirconia Material Types Impact Crown Pricing?

Different zirconia grades and translucency levels influence cost in several ways:

- 3Y Zirconia (High Strength): Most cost-effective; ideal for posterior crowns and bridges, less esthetic demand

- 4Y Zirconia (Balanced): Slightly more expensive; used for esthetic zones with moderate translucency

- 5Y Zirconia (High Translucent): Highest cost; designed for anterior restorations with high esthetic demands

- Porcelain layering options on zirconia cores add additional material and labor costs

Selecting the right grade for the clinical zone prevents overpaying for unnecessary properties.

How Do Labor and Production Processes Affect Zirconia Crown Costs?

Labor intensity varies based on the crown’s design and esthetic expectations.

- Basic monolithic crowns (stained and glazed) require fewer technician hours

- Layered crowns need manual veneering, contouring, and multiple firings

- Complex anatomical adjustments increase technician time significantly

- Additional quality control steps (e.g., microscope margin checks) add time but improve fit

Each added step raises cost—but also reduces risk of chairside adjustment or remake.

How Do Material Grades (3Y/4Y/5Y) Impact Zirconia Porcelain Crown Costs?

| Zirconia Grade | Strength | Esthetic Value | Common Indications | Typical Lab Price Range* |

|---|---|---|---|---|

| 3Y-TZP | Highest | Low | Posterior, bridges | $XX–$XX |

| 4Y-Zirconia | Moderate | Balanced | Premolars, visible areas | $XX–$XX |

| 5Y-Zirconia | Lower | Highest | Anterior, esthetic zones | $XX–$XX |

*Lab pricing varies by region and case complexity. Higher esthetics = higher cost.

Zirconia pricing starts with the material and ends in the chair. Choosing the right grade, layering method, and lab protocol ensures the investment fits the clinical purpose.

How Do Manufacturing Methods Influence the Cost of Zirconia Porcelain Crowns?

Manufacturing methods impact both the quality and cost structure of zirconia porcelain crowns. The choice between manual craftsmanship and digital automation influences technician time, material usage, and consistency—each affecting the final price.

Zirconia-Crown-Manufacturing-Comparison

How Does CAD/CAM Technology Affect the Cost of Zirconia Crowns?

CAD/CAM processes introduce upfront investment but improve downstream efficiency.

- Reduces technician hours through digital design and machine milling

- Lowers human error rates, decreasing remakes and chairside adjustments

- Enables high-volume scalability without proportional labor increase

- Initial equipment and software costs may raise base lab overhead, but amortize with volume

Digital workflows compress cost per unit as production scales—especially for DSO and multi-unit orders.

How Do Sintering and Milling Methods Influence Crown Pricing?

Both processes affect time, precision, and energy consumption.

- High-speed milling units (e.g., 5-axis dry mills) save time but require more expensive blanks

- Slow sintering cycles ensure grain structure stability, but take longer—adding operational cost

- Fast sintering saves time (8–10 hrs vs. 12–16 hrs) but may compromise translucency if not well-calibrated

- Pre-shaded vs. multilayer blanks impact cost based on esthetic demand and labor needed post-milling

Every production decision—speed vs. detail, volume vs. customization—affects price.

How Does Labor Intensity Compare to Automation in Crown Production Costs?

| Production Method | Technician Time | Esthetic Control | Cost per Unit | Risk of Inconsistency |

|---|---|---|---|---|

| Fully Manual (Layered) | High | Highest | Highest | Moderate–High |

| Hybrid (Digital + Manual) | Moderate | Balanced | Moderate | Low–Moderate |

| Fully Digital (Monolithic) | Low | Controlled | Lowest | Low |

Automation streamlines production—but layered artistry still has its place where esthetics take priority.

✅ Digital production lowers per-unit zirconia crown cost through efficiency – TRUE

Labs leveraging CAD/CAM with calibrated protocols can produce consistent, scalable restorations at lower average cost.

❌ Manual techniques always deliver better value than automated methods – FALSE

While layering can elevate esthetics, it often increases cost and variability, especially in posterior or non-esthetic zones.

How Does Customization Level Impact the Cost of Zirconia Porcelain Crowns?

Customization adds value—but it also adds cost. In zirconia porcelain crowns, the degree of customization in shade, shape, and surface texture directly affects the technician’s workload, material choice, and case handling time.

Zirconia-Crown-Customization-Cost

What Additional Costs Are Involved in Shade Matching and Aesthetic Customization?

Color precision takes time and training.

- Custom shade matching sessions (with photos or shade guides) often incur an extra lab fee

- Internal staining and layering increase material use and technician effort

- Multi-layer shade blending for adjacent teeth requires higher esthetic precision

- Special effect powders (cervical translucency, mamelon effect) raise cost due to complexity

High esthetic value comes at the cost of more process steps and skilled labor.

How Do Complex Anterior Designs Affect the Price of Zirconia Crowns?

Anterior cases demand more planning, time, and precision.

- High-smile-line patients require additional esthetic detailing

- Full facial cutbacks for porcelain layering increase prep and veneering time

- Symmetry and incisal translucency often involve trial restorations or digital previews

- Custom try-in sessions may be included or billed separately

The further forward the tooth, the higher the cost of “natural.”

How Does Custom Anatomy Design Influence Zirconia Crown Pricing?

Beyond shade, anatomical detail drives pricing variance.

- Customized occlusal surfaces for opposing wear patterns take longer to mill and finish

- Emulated natural texture (perio-aging, polish-to-glaze balance) involves skilled hands

- CAD customization hours are billed based on case complexity—not just unit count

- Unique morphology may require re-design and re-sintering if not approved in the first pass

True customization goes beyond visual—it includes how the crown functions in each mouth.

Customization reflects both patient expectations and technician craftsmanship. Submit your anterior or esthetic zone case for a detailed customization quote—we’ll help you balance appearance, function, and cost with clarity.

How Do Lab Location and Reputation Influence Zirconia Crown Pricing?

Lab location and reputation don’t just affect shipping times—they significantly impact cost structure, quality consistency, and long-term collaboration value. Price isn’t just about the number on the quote—it’s about what that price includes, or omits.

Zirconia-Lab-Location-Reputation

How Does Lab Location Affect Shipping and Labor Costs?

Geography shapes more than just logistics.

- Domestic labs may have higher labor costs but offer faster adjustments or remake cycles

- Offshore labs often provide lower unit pricing but longer shipping times and higher rework rates

- International freight costs, customs clearance, and courier reliability all factor into total cost

- Localized support (e.g., same time zone, native language) saves time in case discussions

A lower unit price doesn’t always mean lower total spend—especially in time-sensitive cases.

How Does Lab Reputation Affect Crown Pricing and Consistency?

Established labs often price differently—for good reason.

- More experienced teams can handle complex cases more efficiently, reducing chairside risk

- Higher QA standards mean fewer adjustments, less patient frustration, and lower remakes

- Proven track record allows smoother scaling across practices or regions

- Transparent protocols reduce back-and-forth communication and uncertainty

You’re not just buying a crown—you’re buying predictability.

How Do Certifications and Quality Standards Affect Zirconia Pricing?

Certifications signal accountability.

- ISO or FDA-registered labs operate under stricter material traceability and process control

- CE-marked or ADA-accepted materials may cost more but meet clinical compliance standards

- Quality assurance protocols (like lot tracking or batch sintering logs) add cost but ensure case integrity

- Regulatory compliance can also reduce liability and increase patient confidence

These aren’t “add-ons”—they’re cost-justified safeguards.

✅ Lab reputation and compliance standards directly influence zirconia crown quality and pricing – TRUE

Reliable labs bake assurance, support, and consistency into their pricing model—protecting long-term value.

❌ All labs with the same material source offer the same value – FALSE

Material alone doesn’t guarantee result—execution, consistency, and support vary widely by lab capability.

How Do Delivery Speed and Turnaround Time Impact Crown Pricing?

Faster isn’t always better—but it’s rarely cheaper. Delivery speed, including rush orders and international transit, plays a major role in zirconia porcelain crown pricing. Whether you’re optimizing for patient expectations or production flow, timing has a cost implication.

Zirconia-Crown-Turnaround-Cost

How Do Rush Orders Affect the Final Cost of Zirconia Crowns?

Time compression increases operational strain.

- Rush orders often incur express fees ranging from 15% to 50% surcharge per unit

- Priority scheduling displaces other cases, increasing indirect costs

- Higher chance of errors due to accelerated workflow or reduced drying/sintering time

- Technician overtime or weekend shifts are typically passed on in final pricing

Rush pricing protects the workflow, not just the delivery deadline.

What Shipping Cost Differences Exist Between Domestic and International Orders?

Shipping isn’t just a courier fee—it’s part of the operational budget.

- Domestic express shipping is faster but can be costly in remote areas

- International deliveries add customs, insurance, and transit time buffers

- Bulk shipments can reduce per-unit freight but raise turnaround risk if delayed

- Shipping reliability matters more than speed—lost cases cost more than delayed ones

Labs factor risk and cost volatility into international pricing.

How Does Delivery Speed Influence Zirconia Crown Pricing?

Lead time expectations shape how labs structure pricing tiers.

- Standard lead times (5–7 days lab time) align with base pricing

- Accelerated cycles (2–3 days) often involve dedicated resources and premium blanks

- Ultra-fast options (24–48 hours) are feasible but priced for disruption control

- Hybrid timing (staggered multi-unit cases) may split cost across phases

Turnaround-based pricing helps labs protect quality while meeting demand.

Delivery speed is a logistics lever—but it’s also a cost driver. Request our turnaround time guide or explore custom delivery arrangements tailored to your practice’s needs.

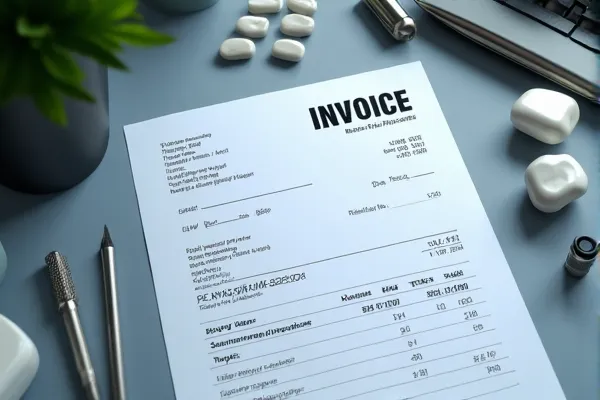

What Hidden Costs Should Be Considered in Zirconia Porcelain Crown Pricing?

A quote only tells part of the story. Beyond base unit price, hidden costs like remakes, adjustment fees, payment terms, and unclear warranty policies can impact total case cost—and sometimes, practice profitability.

Hidden-Zirconia-Costs-Dental-Lab

What Are the Cost Implications of Remakes and Adjustments in Zirconia Crowns?

Remakes are rarely “free.”

- Out-of-policy remakes (due to prep design or impression error) are often charged in full

- Adjustment fees apply for contact, shade, or marginal corrections post-delivery

- Chairside time lost due to remakes or poor fit translates to indirect practice cost

- Shipping costs for remake returns may not be covered, especially internationally

Review the remake window and exclusions carefully—it’s often where costs add up.

How Do Warranty and Remake Terms Influence the Total Cost of Zirconia Crowns?

Not all warranties protect equally.

- Limited time coverage (e.g., 30–90 days) may not align with patient follow-up schedule

- Material-only warranties don’t include technician time or shipping

- Case-by-case approvals delay remake timelines and introduce administrative overhead

- Lack of clearly written policies can lead to billing surprises and patient dissatisfaction

Clear remake and warranty terms are just as valuable as the crown itself.

What Payment Conditions and Hidden Charges Affect Zirconia Crown Pricing?

Financial terms are rarely discussed—but they matter.

- Rush or priority billing fees often added after the fact if not clarified at order

- Late payment penalties or interest can raise project cost significantly

- High minimum order values may disqualify small clinics from base pricing

- Case revision fees (e.g., digital design change mid-production) may not be quoted upfront

A “low quote” can easily become a “high invoice” without transparent financial terms.

✅ Hidden costs like remakes, warranty gaps, and payment terms can significantly affect total zirconia pricing – TRUE

Understanding service conditions is essential to evaluate true lab value.

❌ The lowest unit price always delivers the lowest overall cost – FALSE

When hidden fees and inconsistencies emerge, the total cost often exceeds that of more transparent providers.

How to Evaluate the Best Value When Choosing Zirconia Porcelain Crowns?

Price is just one part of the equation. Evaluating the true value of zirconia porcelain crowns requires comparing more than unit cost—considering durability, esthetics, reliability, and long-term service standards across labs.

Image

ALT: Zirconia-Crown-Value-Comparison

Prompt: A realistic comparison chart on a dental consultant’s desk showing pricing, service terms, remake policy, and esthetic results across three different labs—highlighted with crown samples and evaluation forms

How to Compare Prices from Different Labs?

Direct price comparison requires aligned criteria.

- Request all-inclusive quotes, covering design, layering, shipping, and potential remake fees

- Ask for typical turnaround time and clarify rush case handling terms

- Check if design previews or digital wax-ups are included or extra

- Verify what the price includes: staining, anatomy adjustments, or only base units?

A price per unit is only fair if the deliverables per unit are clear.

How to Balance Cost with Durability and Aesthetic Quality?

Don’t sacrifice performance for short-term savings.

- Low-cost options may use basic monolithic zirconia without customization

- Mid-range labs often strike a better balance of esthetic layering and reliable turnaround

- Premium labs invest more in both skilled labor and verified materials

- Evaluate case history: How often does the crown need adjustment or remake?

Long-term value often lies in fewer remakes—not just lower line items.

What Factors Should Be Prioritized for Maximum Value?

Value = performance over time, not just initial pricing.

- Consistent quality reduces chairside time and repeat appointments

- Reliable turnaround keeps patient timelines predictable

- Transparent remake and warranty terms protect practices from cost surprises

- Strong lab communication prevents misalignment and costly rework

Crown value is earned in delivery and performance—not promised in a quote.

Understanding zirconia crown value goes beyond price. Assess what’s included, how reliably it’s delivered, and what protection is in place if things go wrong. That’s how real value—and trust—is built.

Conclusion

Zirconia porcelain crown pricing reflects more than just material cost—it encompasses craftsmanship, production methods, logistics, and long-term reliability. Evaluating these factors holistically ensures better budgeting and better restorative outcomes for clinics and patients alike.

- Crown pricing begins with core components such as zirconia grade, layering method, and technician time that define base value.

- Digital workflows and sintering choices also influence crown cost based on production speed, precision, and consistency.

- High levels of esthetic customization impact pricing through labor intensity, materials, and esthetic planning time.

- Where and how the lab operates can affect crown pricing through shipping, labor rates, and reputation-based premiums.

- Faster turnaround adds cost due to rush handling, priority scheduling, and delivery risk management.

- Beyond quotes, clinics must consider hidden costs like remakes, adjustment fees, and warranty terms in the total budget.

- Smart procurement teams focus on balancing cost, durability, and esthetic outcomes rather than defaulting to the lowest unit price.

- True value comes from understanding what the price includes and how the lab supports case outcomes—not just the number.

Looking to clarify what’s included in your zirconia crown pricing? Contact our team for a transparent quote and value breakdown that matches your clinical and esthetic expectations.