3D printing is redefining dental implant lab workflows by combining speed, precision, and digital integration. From rapid prototyping to patient-specific restorations, additive manufacturing streamlines production, shortens turnaround times, and reduces costs by minimizing waste and manual labor. This transformation positions dental labs to meet growing demands with greater consistency and scalability.

Key dimensions of this transformation include:

- Production speed – Implant components, models, and surgical guides can now be produced within 24 hours.

- Efficiency – Digital scans connect directly to 3D printers, eliminating manual steps and reducing errors.

- Quality – Highly accurate, patient-specific fits and precise surgical guides improve long-term outcomes.

- Strategic value – Labs gain productivity, scalability, and competitive differentiation in a global market.

- Practical challenges – Upfront equipment costs, staff training, and regulatory requirements must be addressed.

For procurement and lab decision-makers, the shift to 3D printing is not only about adopting new technology—it is about reshaping workflows to achieve faster, more accurate, and more cost-effective implant solutions. Embracing this transformation enables labs to deliver consistent value, build stronger partnerships, and stay ahead in an evolving dental industry.

Why Is 3D Printing Considered a Game-Changer for Dental Implant Labs?

3D printing is considered a game-changer because it combines speed, precision, and cost savings in ways that traditional methods cannot. For dental implant labs, this technology means faster case delivery, more customized restorations, and reduced production costs—all of which directly improve client satisfaction and lab competitiveness.

How does 3D printing deliver faster, more precise results than traditional methods?

3D printing bypasses mold creation and multiple manual steps, building restorations layer by layer directly from digital scans.

- Speed: Surgical guides can be printed within hours rather than waiting a week for casting or milling.

- Precision: Digital slicing ensures micron-level accuracy, minimizing manual adjustment.

- Consistency: The same file can produce identical results across multiple cases.

This digital-first approach allows labs to deliver more predictable outcomes in less time.

How do highly customized restorations expand treatment options?

Customization is a critical differentiator. With 3D printing, labs can produce patient-specific guides, temporaries, and full-arch solutions that match clinical requirements. This enables dentists to offer a broader set of treatment plans, from complex implant cases to immediate loading protocols. For example, a global dental lab supporting DSOs can deliver both single-unit restorations and complex multi-unit guides in one production cycle, offering flexibility that traditional processes cannot.

How does 3D printing create cost savings by minimizing material waste and reducing manual labor?

Unlike milling, which carves away material, additive manufacturing deposits only what is needed. This reduces waste of costly resins or metals. At the same time, digital workflows eliminate repetitive manual labor like wax-ups and mold adjustments, which not only saves time but also lowers staffing costs. Published data from the Journal of Prosthetic Dentistry highlights that labs adopting 3D printing see both reduced expenses and more efficient use of technician time.

By combining speed, customization, and cost control, 3D printing redefines what labs can achieve. As an overseas dental lab, Raytops has found that clients view this technology not just as an innovation but as a baseline expectation for modern collaboration.

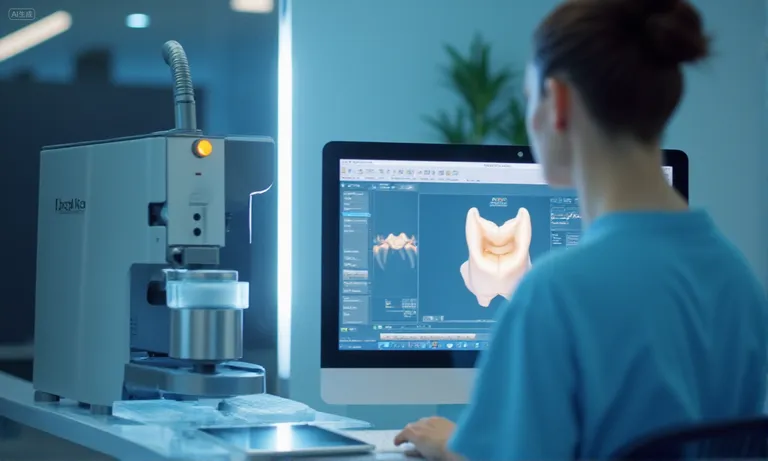

How Does 3D Printing Reshape the Production Process?

3D printing reshapes the production process by enabling rapid prototyping, error reduction, and in-house fabrication. These changes give labs greater control over timelines, quality, and cost, transforming the way implant restorations are manufactured and delivered.

Dental-lab-3D-printing-production-process

How can labs prototype and produce implant components in as little as 24 hours?

With 3D printing, labs can move from scan to physical model in a single day.

- Digital design: Clinicians send intraoral scans directly to the lab.

- Prototyping: Surgical guides or provisional crowns can be printed overnight.

- Iteration: Design adjustments are done digitally, avoiding repeated physical mold-making.

This cycle compresses what once took weeks into 24–48 hours, allowing clinics to treat patients faster and labs to manage more cases simultaneously.

How does additive manufacturing minimize errors and material waste?

Unlike milling or casting, additive manufacturing builds only what is needed, ensuring precision and efficiency.

| Factor | Traditional Milling/Casting | Additive 3D Printing |

|---|---|---|

| Material use | Subtractive (high waste) | Additive (minimal waste) |

| Error risk | Manual steps increase risk | Digital precision reduces errors |

| Production consistency | Varies by technician | Consistent across batches |

This reduces both financial waste and clinical risk, making workflows more predictable.

How does in-house fabrication reduce reliance on external suppliers and molds?

In-house 3D printing allows labs to fabricate parts without outsourcing to third-party suppliers or relying on multiple mold systems. This not only eliminates shipping delays and external markups but also gives labs more flexibility in scheduling urgent cases. For DSOs managing many clinics, in-house production means reliable case delivery without bottlenecks. As a global dental lab, Raytops has seen how controlling production internally reduces uncertainty and strengthens client confidence.

By shifting production from manual, external, and waste-heavy processes to digital, in-house, and highly efficient workflows, 3D printing redefines how dental implant labs operate.

What Efficiency Gains Do Labs Achieve with 3D Printing?

3D printing delivers efficiency gains by streamlining workflows, reducing manual intervention, and enabling seamless clinic–lab integration. These improvements help labs manage higher volumes while maintaining consistency, speed, and quality.

Dental-lab-3D-printing-efficiency-gains

How does a streamlined digital workflow connect scan to final product?

3D printing simplifies the journey from intraoral scan to final restoration.

- Scans are imported directly into CAD software.

- Files are digitally sliced and sent to printers.

- Post-processing ensures fit accuracy and delivery readiness.

By removing mold-making and analog transfers, labs can complete cases faster and with fewer errors, giving clinics quicker turnaround.

How does automation reduce manual steps and improve consistency?

Automation shifts many labor-intensive steps into software-driven processes.

| Workflow Step | Traditional Method | With 3D Printing |

|---|---|---|

| Wax-ups | Manual sculpting | CAD design automated |

| Mold preparation | Casting/investment | Digital slicing |

| Adjustments | Frequent chairside fixes | Reduced due to precision printing |

This minimizes human error while ensuring every case follows the same predictable process.

How does seamless digital integration support clinic–lab collaboration?

Digital integration creates a direct channel between clinics and labs. Scans, designs, and approvals are exchanged electronically, cutting delays in communication. For DSOs, this allows multiple clinics to collaborate with a single lab in real time. As an overseas dental lab, Raytops has seen clinics value this transparency—knowing their designs are visible at each stage reduces anxiety about turnaround and fit outcomes.

These workflow efficiencies not only cut costs but also increase trust, as clinics receive restorations faster, with higher precision and fewer disruptions.

How Does 3D Printing Improve Quality and Accuracy in Implant Restorations?

3D printing improves quality and accuracy by enabling patient-specific fit, precise surgical guidance, and reduced remake rates. These improvements not only support better clinical outcomes but also save labs time and resources by minimizing errors and adjustments.

Dental-lab-3D-printing-accuracy-quality

How does patient-specific fit ensure comfort and better long-term outcomes?

3D printing enables restorations and guides that are tailored to each patient’s anatomy. Unlike standardized molds, digital workflows capture unique intraoral details, producing prosthetics that fit more naturally. This precision translates into:

- Better occlusion and bite alignment.

- Reduced chairside adjustments for clinicians.

- Improved comfort and long-term durability for patients.

For procurement teams, patient-specific accuracy means fewer complaints and greater trust in the lab’s capabilities.

How do highly accurate surgical guides enhance implant placement precision?

Surgical guides are one of the clearest examples of 3D printing’s impact.

- Precise angulation: Guides ensure implants are placed at the correct depth and angle.

- Reduced surgical risk: Accuracy lowers the chance of complications during placement.

- Predictable outcomes: Clinicians can plan restorations in advance, knowing placement will match design.

These benefits shorten chair time and increase clinician confidence, making labs with 3D printing more attractive partners.

How do fewer remakes and adjustments reduce delays for labs?

High accuracy reduces errors that lead to remakes, which are costly for both labs and clinics.

- Fewer misfits mean fewer rejected cases.

- Reduced adjustment time speeds up final delivery.

- Consistency across batches minimizes disruptions.

An overseas dental lab like Raytops has seen that lowering remake rates directly improves client satisfaction. For DSOs managing multiple practices, this consistency is essential to scaling operations without added complexity.

By improving fit, precision, and reliability, 3D printing ensures higher-quality outcomes that strengthen both clinic–lab trust and long-term procurement strategies.

What Strategic Benefits Does 3D Printing Offer Dental Labs?

3D printing offers strategic advantages that go beyond cost or efficiency. By expanding service capabilities, improving scalability, and strengthening client partnerships, labs can position themselves as long-term collaborators rather than transactional vendors.

Dental-lab-3D-printing-strategic-benefits

How do expanded service capabilities create competitive differentiation?

3D printing allows labs to provide services that traditional workflows cannot match—such as immediate surgical guides, same-day provisional crowns, and full-arch solutions with patient-specific fit. This range of options helps labs stand out in competitive markets. Clinics and DSOs increasingly see these services as must-haves, meaning labs without 3D printing risk being overlooked in tenders and partnerships.

How does 3D printing increase productivity and long-term scalability?

Adopting 3D printing creates a foundation for sustainable growth.

- Higher case throughput without proportionally adding staff.

- Scalable production capacity to support DSOs with multiple clinics.

- Flexible manufacturing to adapt quickly to urgent or complex cases.

This scalability ensures that labs can grow alongside their clients without sacrificing turnaround or quality.

How does adopting 3D printing strengthen lab–client relationships?

Technology adoption is also a relationship strategy.

| Strategic Factor | Without 3D Printing | With 3D Printing |

|---|---|---|

| Service offering | Limited restorations | Expanded portfolio (guides, provisionals, full-arch) |

| Client confidence | Variable outcomes | Consistent, predictable delivery |

| Partnership potential | Transactional | Strategic, long-term collaboration |

Labs that integrate 3D printing are seen not just as suppliers but as partners in solving client challenges. Raytops, as an overseas dental lab, has observed that offering scalable, advanced services fosters stronger ties with DSOs and distributors, leading to repeat contracts and mutual growth.

By enhancing differentiation, scalability, and client trust, 3D printing positions labs for long-term strategic success in a rapidly evolving industry.

What Challenges and Considerations Come with 3D Printing Adoption?

While 3D printing provides significant benefits, adoption also requires labs to navigate financial, operational, and regulatory challenges. Understanding these considerations helps procurement teams and labs plan for sustainable integration rather than short-term gains.

Dental-lab-3D-printing-adoption-challenges

What are the equipment investment and ongoing maintenance costs?

3D printing requires an upfront investment in hardware and materials, often higher than traditional equipment. Ongoing costs include resin or metal powders, replacement parts, and machine servicing. While these expenses are offset by reduced labor and waste, labs must carefully evaluate ROI timelines. For buyers, a lab that openly shares cost structures and capacity planning demonstrates transparency and reliability.

How can labs upskill teams for digital and 3D printing workflows?

Adopting 3D printing demands new skill sets for technicians and managers.

- CAD/CAM design: Training ensures technicians can manage digital workflows effectively.

- Printer operation: Staff must learn machine calibration, material handling, and troubleshooting.

- Post-processing: Finishing steps, such as curing or polishing, require specialized techniques.

- Workflow management: Supervisors must adapt to digital scheduling and file-sharing platforms.

Investing in training prevents bottlenecks and builds confidence in consistent case delivery.

How can labs meet regulatory and certification requirements for 3D-printed devices?

Compliance is essential for gaining trust and market access. Labs should follow a structured process:

- Identify regulations: CE, FDA, or local medical device rules.

- Validate materials: Ensure all resins, metals, or polymers are approved for dental use.

- Document processes: Maintain traceability for every printed part.

- Undergo audits: Periodic inspections confirm compliance with quality standards.

An overseas dental lab like Raytops has seen how meeting regulatory requirements not only satisfies legal obligations but also reassures clients about the safety and durability of printed restorations.

By addressing costs, training, and compliance, labs can adopt 3D printing responsibly—ensuring innovation is paired with reliability and trustworthiness.

Conclusion

3D printing has moved from novelty to necessity in dental implant lab workflows. By reducing waste, accelerating turnaround, and improving accuracy, it delivers measurable value for clinics and procurement teams. Beyond operational gains, labs that embrace additive manufacturing position themselves as strategic partners capable of scaling with client demand. For buyers, partnering with an overseas dental lab that combines advanced 3D printing expertise with proven quality systems ensures both immediate savings and long-term reliability. In today’s competitive market, technology-driven collaboration is not just an advantage—it is the foundation for sustainable growth in implant restorations.