Evaluating a dental lab’s digital workflow goes beyond checking for scanner support—it’s about whether their system consistently delivers precision, efficiency, and traceability in demanding crown and bridge cases. For procurement teams, the real differentiator is not whether a lab accepts digital files, but whether they’re engineered for seamless, multi-platform collaboration across design, approval, and production.

From material compatibility to turnaround speed, digital labs vary widely in execution. Key areas to assess include:

- Clinical readiness: Can they manage the demands of crown & bridge workflows with anatomical accuracy?

- Product scope: Do they support zirconia, layered, anterior, and implant-supported restorations?

- System interoperability: Are common scanners and CAD platforms natively supported?

- Quality control: Are margin lines, designs, and remakes documented and traceable?

- Logistics reliability: Are turnaround times predictable across case types?

- Communication flow: Are design approvals, changes, and feedback loops documented in real time?

- Procurement alignment: Can you qualify them using a clear, question-led evaluation framework?

These benchmarks help procurement leaders identify labs that aren’t just “digital-capable,” but digitally dependable—capable of supporting scalable, cross-border partnerships with clarity and confidence.

Why Digital Workflow Matters for Crown and Bridge Cases

A well-executed digital workflow significantly reduces errors, ensures better clinical fit, and enhances collaboration for crown and bridge cases—where complexity and consistency are critical. Unlike single-unit restorations, multi-unit bridge work demands advanced design coordination and precise margin adaptation. Digital systems provide the consistency and traceability needed to manage this complexity effectively, making it essential for labs serving demanding restorative cases.

digital-crown-bridge-workflow-accuracy

How does digital production improve accuracy and consistency?

Digital workflows reduce guesswork by enabling pixel-level control across scanning, design, and milling. For crown and bridge cases, this accuracy directly affects marginal fit, connector dimensions, and overall occlusion consistency.

- Margin clarity and reproducibility: Intraoral scanners paired with software like 3Shape’s Margin Line Wizard help define precise finish lines, reducing the risk of over-trimming or distortion.

- Design uniformity across units: For multi-unit bridges, digital libraries and anatomical templates ensure consistent morphology and connector strength.

- Reduced remake rate: From our lab’s tracked cases, digitally planned zirconia bridges showed a 27% reduction in remakes compared to conventional workflows, due to better upstream data quality.

This consistency is particularly beneficial when collaborating with clinics that use mixed scanner systems or work across locations—highlighting the advantage of a unified digital workflow.

What makes crown and bridge workflows more demanding than single-unit cases?

Crown and bridge workflows introduce exponential complexity in design coordination, case communication, and margin integration. Unlike single-unit crowns, bridge cases require managing:

- Multiple abutments with parallel path of insertion

- Connector thickness and anatomical alignment

- Material shrinkage across long-span restorations

In one example, a DSO partner in Canada faced repeated connector failures in traditional frameworks. Once we transitioned them to a full-digital zirconia bridge design with digital connector analysis, failure rates dropped dramatically.

These challenges amplify with the number of units involved. The lab’s ability to digitally simulate stress points, validate connector geometry, and match occlusal schemes across arches becomes vital.

How does digital workflow improve patient satisfaction and clinical outcomes?

Digital workflows improve fit, esthetics, and turnaround—all factors that directly impact the patient experience. When labs deliver high-precision restorations, chairside adjustment times drop and esthetic outcomes improve.

- Fewer seating appointments: Digital fit verification reduces need for secondary impressions or occlusal adjustments.

- Predictable esthetics: Layered zirconia or full-contour designs are color-matched using standardized shade guides with consistent lighting, improving patient confidence.

- Speed and traceability: Real-time production tracking helps clinics schedule seating appointments accurately, improving both provider efficiency and patient perception.

One clinic in Brisbane noted that, after shifting to our fully digital protocol for 5-unit bridges, their average chairside adjustment time dropped from 18 minutes to under 7—reducing appointment stress for both the clinician and patient.

Digital workflows don’t just streamline manufacturing; they improve clinical harmony and patient trust.

What Capabilities Should a Lab’s Digital Workflow Cover?

A qualified lab should be able to handle the full spectrum of digital restorative demands—from anterior esthetics to full-arch structural integrity. Crown and bridge work varies widely in complexity, and a lab’s ability to support different material types, design challenges, and case scales is a direct reflection of their readiness for long-term collaboration.

digital-dental-lab-zirconia-bridge-design

Do they support full-contour, layered, and anterior zirconia restorations?

A versatile lab should master both esthetic finesse and functional strength across zirconia types. Each case type requires different design protocols and technician skill sets.

- Full-contour zirconia: Ideal for posterior strength; labs must control sintering shrinkage and occlusion depth.

- Layered zirconia: Used for anterior esthetics; layering protocols must match substrate shades precisely and avoid chipping risks.

- Translucent anterior zirconia: Demands color mapping and digital shade communication, especially for smile zone cases.

At Raytops Dental Lab, we often collaborate with clinics on complex esthetic cases where patients demand natural translucency. We use digital photography and shade scan protocols to translate chairside expectations into production-ready designs.

Can the lab handle implant-supported and full-arch bridge cases?

Handling implant-supported or full-arch cases is a benchmark for lab sophistication. These cases involve advanced design validation, cross-arch fit accuracy, and digital verification points.

| Case Type | Design Requirements | Digital Capabilities Needed |

|---|---|---|

| Implant-supported bridges | Multi-platform abutment design, screw channel accuracy | Verified STL workflows; library merging |

| Full-arch zirconia | Precise fit, balanced occlusion, esthetic masking | Cross-arch simulation; passive fit test |

| Hybrid solutions | Metal framework + acrylic or composite overlay | Dual-material planning; offset control |

We recently supported a mid-sized lab in the U.S. that was scaling up full-arch demand. By integrating passive fit simulations and real-time connector feedback, they reduced seating issues and cut remake rates by 31% over two quarters.

How do they manage design complexity for multi-unit bridge structures?

As bridge span increases, so does the risk of design failure—especially in connector geometry and anatomical harmony. A capable lab must proactively manage this complexity through intelligent CAD/CAM processes.

- Connector shape validation: Ensuring strength without overbulking

- Pontic profile customization: Adapting to patient tissue contour and hygiene

- Digital design layering: Managing multiple units with anatomical synchronization

One of our European partners—an independent lab in Rotterdam—encountered recurring tissue impingement due to oversized pontics from outsourced designs. After switching to a more collaborative digital design phase with us, their cases showed smoother gingival transitions and improved long-term comfort reported by clinicians.

How Compatible Is the Lab’s Workflow with Your Digital Tools?

A digitally mature lab should offer seamless compatibility with your existing intraoral scanners, CAD/CAM software, and workflow platforms—without requiring excessive format conversion or manual adjustment. Compatibility is not just about file types; it’s about how well their system integrates with yours to avoid bottlenecks, rework, and miscommunication.

dental-cad-integration-scanner-file-import

Do they accept files from iTero, Trios, Medit, and other common scanners?

Scanner compatibility is a baseline requirement, not a premium feature. Labs should seamlessly accept native output formats from the most widely used intraoral systems:

- iTero (.iScan, .STL)

- 3Shape Trios (.3oxz, .PLY)

- Medit (.STL, .OBJ)

- Carestream, Planmeca, and others (.STL compatible)

We often support multi-location DSOs using a mix of Trios and Medit across their clinics. Through direct uploader portals, they’re able to submit cases without conversion or local export—saving an average of 7–10 minutes per case.

Labs relying only on manual uploads or restricted file types create unnecessary friction. That’s why full native import support should be a key evaluation criterion.

What CAD/CAM platforms (e.g. Exocad, 3Shape) are supported?

A well-integrated lab should work within the same CAD/CAM ecosystem as your clinic or partner lab. This reduces interpretation errors and simplifies file versioning and update syncing.

| CAD/CAM Platform | Common Use Cases | Typical Client Benefits |

|---|---|---|

| 3Shape | Crown/bridge, full-arch | High anatomical libraries, real-time viewer |

| Exocad | Implant, removable, hybrid | Open architecture, API support |

| Dental Wings | Some DSOs and legacy setups | Compatibility with older systems |

We recently assisted a Canadian group that had adopted Exocad for all anterior workflows. Our ability to return files in native Exocad project format (.dentalProject) eliminated manual touch-ups and sped up turnaround by two days per case on average.

Do they offer flexible integration options such as APIs or automation tools?

Modern labs offer more than uploads—they offer workflow bridges. This includes custom API-based integration, case tracking dashboards, and even automated status updates into your existing clinic software.

In one example, a European distributor needed real-time sync between their client portal and our lab system. We deployed a lightweight webhook setup that allowed their platform to receive design approval status automatically—reducing technician email load by 43% in the first month.

Even for smaller clinics, simple dashboard access to live case status (e.g., “in design,” “awaiting approval,” “in production”) adds clarity and reduces inquiry loops. These automation tools reflect the lab’s operational maturity and readiness for scalable cooperation.

How Is Quality Assured in the Digital Workflow?

Reliable labs integrate multi-stage checks, visual documentation, and digital traceability into their workflow to reduce remakes and ensure clinical precision. Quality assurance (QA) in a digital context is not just final inspection—it begins at design input and continues through every milestone. For crown and bridge work, where margins, connectors, and anatomy must align precisely, a robust QA system is non-negotiable.

dental-lab-margin-validation-quality-check

Are there approval points before design finalization?

An effective digital QA system allows clinicians or procurement leads to review and approve key design steps before manufacturing. This not only reduces downstream errors but also aligns expectations early.

- Pre-production approval: Some labs offer a mid-stage viewer (like 3Shape Communicate or Exocad web viewer) for clinicians to review margin lines, connectors, or shade placement.

- Layered cases approval: For esthetic zirconia, labs may send screenshots or videos of cutback design before pressing.

- Change-tracking: Labs with robust digital systems document design iterations and approvals, reducing confusion when multiple technicians are involved.

In a recent collaboration with a UK-based clinic, we implemented pre-design approval checkpoints for their high-anterior esthetic cases. This eliminated repeated adjustments and shortened final turnaround time by nearly two days.

Do they provide visualized remake records and traceable digital logs?

A reliable lab documents every case stage digitally—including redesigns, remakes, or return reasons—and shares this with clients when needed. This transparency builds long-term trust and helps identify systemic issues.

| QA Feature | Benefit to Clinic |

|---|---|

| Visual remake records | Identify root causes (e.g., scan issue vs. design) |

| Technician notes per case | Understand decisions and file adjustments |

| Time-stamped approvals | Resolve disputes and clarify feedback chains |

We recently handled a situation where a returning crown was flagged as “open margin.” Our system showed the original scan had unclear interproximal data. The clinic revised their scan protocol after this, and remake requests in similar cases dropped by 40% in two months.

How does the lab validate margin lines and anatomical fit?

Final validation includes margin line checks, occlusion simulation, and connector integrity testing before milling. These aren’t just software clicks—they require trained technicians to interpret and verify outcomes.

- Margin tracing tools: Tools like Margin Wizard or visual overlays are used to verify prep clarity.

- Occlusion simulation: Multi-unit bridges undergo virtual articulation and pressure mapping before export.

- Connector integrity check: Labs often set minimum connector thickness thresholds in design settings to prevent fracture risk.

One client lab in Australia experienced recurring connector failures on 4-unit posterior bridges. After reviewing their exports, we found connector thickness had been set below the 4mm minimum. After realigning on digital design standards, their fracture rate dropped by 16% within one quarter.

How Efficient and Reliable Is the Turnaround Time?

A dependable lab should provide consistent turnaround times with transparency across restoration types and offer realistic rush options when needed. Inconsistent lead times and vague timelines often lead to patient dissatisfaction, rescheduled appointments, and unnecessary stress for clinicians. Digital workflows should improve—not obscure—your planning accuracy.

dental-lab-turnaround-time-dashboard

What is the standard lead time for zirconia crown and bridge cases?

For typical crown and bridge cases, digital labs should offer clear timeframes with process breakdowns. Average times range depending on unit count, material, and geography.

- Single posterior zirconia crown: 4–5 working days (excluding shipping)

- 3-unit zirconia bridge: 5–6 working days

- Layered anterior zirconia: 6–7 working days, due to extra design and cutback steps

At Raytops, we structure our production line by case complexity. For high-frequency clients, we implement batch shipping twice weekly, enabling predictable delivery cycles without idle waiting.

How long do full-arch or implant-supported cases typically take?

These cases demand more design collaboration and validation steps, increasing total turnaround time. But a capable lab will front-load design planning to streamline the back end.

| Case Type | Design Complexity | Avg. Turnaround Time |

|---|---|---|

| Full-arch zirconia | High | 10–12 working days |

| Implant-supported bridge | Medium-High | 9–10 working days |

| Hybrid denture (metal base) | Very High | 12–15 working days |

We once supported a DSO in California scaling up their full-arch restorations. By running digital design approval rounds in parallel with model prep, we helped them trim 2.5 days from the full-arch timeline across 20+ cases.

What is the process and cost for urgent or rush digital cases?

Rush cases are common—but they require a clear system and cost structure. Labs should offer an accelerated path that doesn’t compromise quality, and clients should be able to identify when and how it applies.

- Rush eligibility criteria: Case must be digitally scanned with complete files, clear prep margins, and no layering requirements.

- Typical rush lead time: 48–72 hours (excluding shipping)

- Rush surcharge: 20–30% depending on case complexity and materials

A Canadian clinic once contacted us at 9 AM on a Monday with a fractured posterior crown and patient travel scheduled that Friday. Because the scan was clean and shading straightforward, we delivered a full-zirconia crown by Thursday morning—avoiding a cancelled appointment and securing the clinic a loyal referral.

How Clear and Responsive Is the Communication Process?

Clear, documented, and real-time communication is essential to minimize delays and misunderstandings—especially in cross-border dental collaborations. Labs that invest in digital collaboration tools not only improve turnaround efficiency but also reduce the risk of misaligned expectations. A strong communication process is one of the most underestimated quality indicators in digital workflows.

dental-lab-real-time-case-communication-interface

Do they offer real-time platforms for reviewing and approving case designs?

Modern labs should provide collaborative tools that let clients review, comment, and approve cases in real time. This is especially critical for multi-unit or esthetic cases, where visual clarity and prompt input can prevent costly delays.

- Case viewers with annotation: Platforms like 3Shape Communicate allow drawing on screenshots and 3D models.

- Real-time design chats: Some labs offer direct chat with designers during case staging.

- Integrated approval buttons: Design sign-offs should be digital and timestamped, reducing ambiguity.

We once worked with a New Zealand-based clinic operating in GMT+13. Through asynchronous but documented design feedback on our platform, they were able to approve cases overnight, and we could mill them the same day—cutting total production time by 1.5 days on average.

Is all communication documented and traceable within the system?

Email chains are not enough. Every design discussion, approval, or adjustment must be linked to the specific case file for full accountability.

| Communication Layer | Traceability Method | Value for Clinic |

|---|---|---|

| Case design revisions | Logged change history | Avoids misunderstanding over versions |

| Approval timestamps | System-logged with user ID | Prevents disputes on sign-off timing |

| Technician notes | Centralized in case management system | Enables multi-role collaboration |

In one case, a European group escalated a “wrong shade” complaint. Our system showed that the final shade was approved with a signed digital screenshot by their coordinator—allowing the issue to be resolved without blame or financial conflict.

Do they provide digital consultation or technician support for workflow issues?

Responsiveness isn’t just speed—it’s availability of the right expertise when needed. Labs should offer technical liaisons or case advisors who understand both the CAD/CAM side and chairside priorities.

- Dedicated case managers: Especially for multi-location DSOs

- Issue resolution windows: Protocols for responding to design changes, scan uploads, or urgent queries within specific hours

- Training support: Some labs offer quick guides or videos to help with scanner settings, file exports, or case submission

We partnered with a U.S. chain that experienced frequent scan distortion due to improper file export settings from Trios. Our technician reviewed one case via screen share, diagnosed the export error, and sent a quick tutorial video. Remakes from scan errors dropped to near zero in two weeks.

What to Ask When Evaluating a Lab’s Digital Readiness

Before committing to a new lab partner, clinics and DSOs should ask targeted questions to evaluate digital maturity—not just capability claims. Knowing what to ask helps expose workflow gaps, hidden costs, and compatibility issues that can otherwise surface after production begins. A checklist approach turns a vague conversation into a structured vendor evaluation.

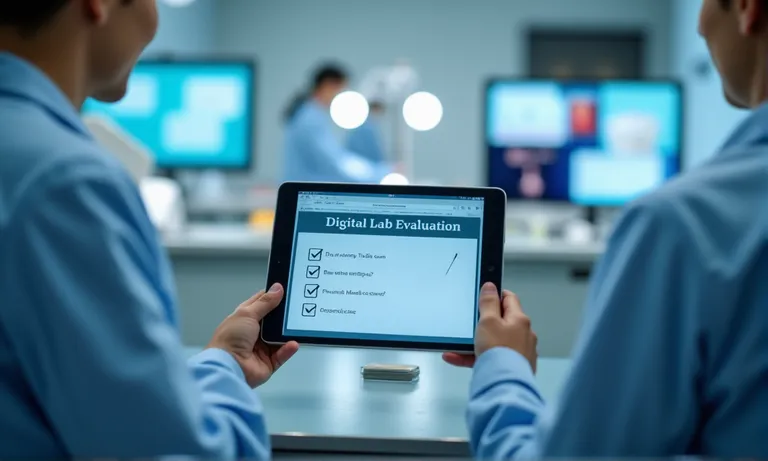

digital-lab-evaluation-checklist-on-tablet

What tools and software do they actively support and update?

A reliable lab should provide a transparent list of supported scanner file formats, design platforms, and real-time communication tools.

- What intraoral scanners are natively accepted (Trios, iTero, Medit, etc.)?

- Which CAD/CAM platforms does your team use (Exocad, 3Shape)?

- How often are these systems updated or synced with client versions?

- Are digital viewers or case approval portals provided?

Some labs say they accept all file types, but that usually means conversion—not native handling. You should verify whether their support means true workflow alignment or just minimal compatibility.

Can they share sample workflows or dashboards that show transparency?

Visualizing how cases flow through the lab builds confidence in consistency and traceability.

| Feature to Request | Why It Matters | What to Look For |

|---|---|---|

| Digital case dashboard | Shows real-time progress and due dates | Time-stamped updates, case logs |

| Approval viewer access | Enables interactive feedback | Annotatable designs, approval history |

| Remake and issue logs | Prevents repeat problems and miscommunication | Linked to each case with technician notes |

We once had a U.S.-based distributor ask for a mock case walk-through before committing. By sharing our real dashboard and approval flow using a sample Trios case, we won their trust—leading to an annual contract for 5,000+ crowns.

What onboarding support is provided for new digital customers?

Even a highly capable lab is only as good as its ability to help you get started smoothly. Onboarding support should go beyond a pricing sheet.

- Is there a dedicated technician or support team for your onboarding period?

- Will they review your scanner settings or guide your first case submission?

- Do they offer feedback loops on scan quality, margin prep, or common errors?

In our experience, onboarding is not just technical—it’s cultural. For one independent clinic in the UK, our initial 3-case trial included daily check-ins, design previews, and margin feedback. After onboarding, their case rejection rate dropped from 12% to under 2%.

Conclusion

Choosing the right dental lab for crown and bridge work goes beyond material selection—it’s about digital compatibility, design precision, transparent processes, and responsive communication. A lab’s ability to integrate with your systems, support complex restorations, and offer traceable quality control is what ensures predictable, scalable results.

As an overseas dental lab with experience serving digital-first clinics and DSOs, we understand how critical seamless workflows and technical alignment are. Whether you’re evaluating for a single-unit trial or scaling multi-site full-arch restorations, the right questions—and the right partner—can make all the difference.